One of the areas where we have seen rapid growth of 3D printing in recent years is in India. This is especially the case when it comes to the construction sector. With additive manufacturing poised as one of the solutions for an ongoing housing crisis, it should come as no surprise that there have been a number of interesting building projects using the technologies in the country, including homes, a post office and the world’s first 3D printed office space. To learn more, we spoke to Kelvin6k, a construction 3D printing company in India that has produced an innovative solution, which they claim to be the most affordable, for the sector.

3DN: Could you introduce yourself and your connection to 3D printing?

We are Kelvin6k technologies, a Chennai, India-based construction 3D printing company. The name Kelvin6k is derived from the surface temperature of the sun (6000 Kelvin) reflecting the company’s keen interest on exploring solar energy for developing additive manufacturing solutions. Kelvin6k was started in the year 2022 with financial support from OnDeck, USA. Since then, the inception company has had a laser sharp focus on revolutionizing construction 3D printing.

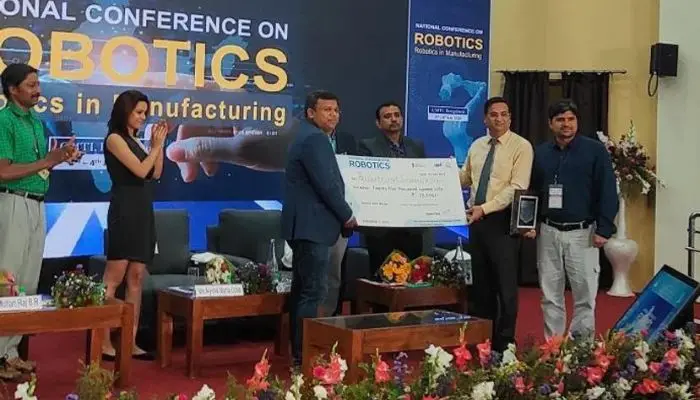

The Kelvin6k team at the National Conference on Robotics in India

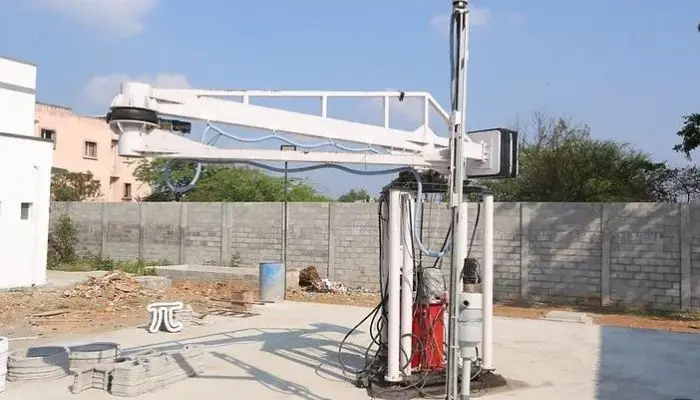

Within a short period of time the company not only developed a series of patented SCARA-based concrete 3D printers but also successfully tested them by printing multiple prints and buildings. We specialize in the creation and production of concrete 3D printing robots, capable of constructing houses on-site. As the exclusive manufacturer in India of concrete 3D printing robots for on-site house printing, our innovative technology is entirely developed in house.

Our robotic printers are dedicated to automating the construction industry and changing the way buildings are created. We also take immense pride in the fact that our robotic printers are the world’s most affordable printers. Furthermore, we are the only Indian company that holds a patent for a complete construction 3D printing machine, a testament to our high quality of innovation.

Kelvin6k is the brainchild of Dr. Pradeepkumar Sundarraj, who is also the CEO and founder of the company. Holding a Ph.D. in Mechanical Engineering, he has worked in several world-renowned research facilities such as NREL, USA, and German Aerospace Center, Germany. He also heads the 3D printer design and robotics department.

Kelvin6k is hoping to innovation construction in India

Besides robotics, designing printable building materials, including both cement-based and sustainable, is another area the company is keenly pursuing. Co-Founder of the company Dr. Ravi Kant Upadhyay, a Ph.D. in Chemistry, oversees the company’s research on this front. He has worked in leading institutions such as the University of Alberta (U of A) Canada, IIT Ropar, and AMPRI (CSIR). Both academicians turned entrepreneurs aims to revolutionize the construction industry by introducing path breaking cutting edge 3D printing technology.

3DN: What is Kelvin6k’s mission?

The company’s mission is to automate construction industry to make house construction process cheaper, greener and faster. Expanding the reach of our technology to the space is another goal company is working towards as we are in process of designing 3D printing technology that can print buildings on Moon and Mars. The underdevelopment 3D printing technology will utilize solar radiation and local dust to print habitats in space.

Our robotic 3D printer ‘Kelvin6k Pro’ is the largest robotic arm-based printer available in India. In 2022, we 3D printed India’s first onsite 3D printed building using a completely ‘Made in India’ robotic 3D printer. Owing to its simplicity and cost-effectiveness, the Kelvin6k Pro printer has garnered interest from all over the world, and also have been hailed as one of the most innovative machines in the field. While other companies are still relying on years old Gantry-based technology and modified industrial robots, Kelvin6k decided to create printer specifically designed for the concrete 3D printing.

The Kelvin6k Pro construction 3D printer

3DN: How does Kelvin6k’s construction 3D printing solution differ from others on the market? What are the benefits of using it?

Conventional and commonly used construction 3D printers are Gantry-based printers, one of the oldest 3D printing technologies. The Gantry-based technology has proven to be highly efficient for printing polymers on lab scale, however in case of concrete 3D printing it suffers due to numerous significant issues such as ultra-high costs, challenging assembly, cumbersome transportation because of heavy weight, and the requirement for frequent maintenance, etc.

Our SCARA-based 3D printers are free of the drawbacks of conventional Gantry-based 3D printers. They are almost ten times cheaper and can be easily assembled onsite within one or two hours. Furthermore, our 3D printers also weigh significantly less, allowing them to be easily transported from one site to another. Our printers have just three moving parts, thus enhancing the lifetime of the machine by limiting possible downtime due to damage to the moving parts and mechanisms.

Apart from Gantry, conventional robotic printers are also another type of 3D printers that are being used currently. Most of these robotic printers are industrial robotic arms with a modified head to print concrete. Since these conventional robotic arms are not exclusively designed for construction printing, they have several major inherent disadvantages such as a short reach and low pay load at the printing head. Most importantly, as these robotic arms are originally designed for more refined industrial applications, therefore the cost of these arms is too high to be considered as a viable option to compete with conventional manual construction practices.

Kelvin6k made the first 3D printed office space in India

During the process of designing our concrete 3D printer ‘Kelvin6k Pro’, we took into account all the disadvantages of both conventional robotic arm and Gantry-based printers, to come up with a printer free of above-described shortcomings.

3DN: What is the importance of AM in construction in India? Could you tell us Kelvin6k’s future projects?

Additive manufacturing holds immense importance in Indian construction industry. Successful inclusion of additive manufacturing will not only expedite the over all construction process but will also make it cheaper and greener. Furthermore, India is facing a huge, ongoing affordable housing crisis. It is estimated that in urban areas, nearly 30 million houses are required in India. The prime reason that has spurred this crisis is the lengthy and costly construction process. This challenge can be addressed by adopting additive manufacturing.

We have several projects in pipeline. We are printing multiple buildings for Indian Air force in different locations. We have also a project planned with ZOHO in upcoming month of January. We are also working on multiple orders for printers we received from all over the world.

The full view of the 3D printed office space

3DN: Any last words for our readers?

Construction 3D printing is the future of the construction and also the only potential solution in sight to solve the ongoing housing crisis. Additive manufacturing has emerged as a new synonym for progress. Every known field has embraced additive manufacturing with open arms. The construction industry is the only industry that has been lagging behind because of its traditional conservative resistance to change.

However, recently, construction 3D printing has witnessed an enormous growth and attention worldwide. Several successful demonstrations of construction 3D printing have been made worldwide, especially in the USA, Dubai, Germany, Canada and India. These technological advancements and their highly celebrated demonstrations hint towards the impending revolution of additive manufacturing in the construction industry. So, we welcome you all wholeheartedly to become part of this ongoing golden rush of concrete 3D printing. “Let’s print the world Layer by layer.” You can find out more on our website HERE.

What do you think of Kelvin6k? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.