The shift to electrification across the automotive sector has intensified moves to improve battery system technologies to facilitate mainstream EV adoption. Two companies collaborating to drive new innovations in ultrafast charging are Castrol, one of the world’s best-known lubricant brands, and Virtual Vehicle Research, a leading international research and development center for the automotive industry, based in Graz, Austria.

From 2021 to 2023 Castrol and Virtual Vehicle undertook analysis of the comparative performance of indirect and immersion cooling technologies. This research was part-funded by the COMET K2 Competence Centers for Excellent Technologies.

This research compared battery cooling via indirect water-glycol baseplate cooling with the increasingly popular system of immersion cooling. Indirect cooling with water-glycol is already well established as the major cooling concept used in today’s EV architectures, due to considerable technology carryover from ICE cooling systems. However, immersion cooling is increasingly being seen as more effective in tackling temperature-management requirements during fast charging of new-generation EVs and improving performance of premium EVs.

While the majority of today’s battery packs are thermally managed using water-glycol-based coolants housed within channels in a baseplate that regulate the temperature of the cells, the dielectric Castrol ON EV thermal fluid has been formulated specifically for immersion cooling. This enables major improvements in thermal management and excellent electrical protection in a range of operating conditions, at high and low ambient temperatures, for a longer battery life.

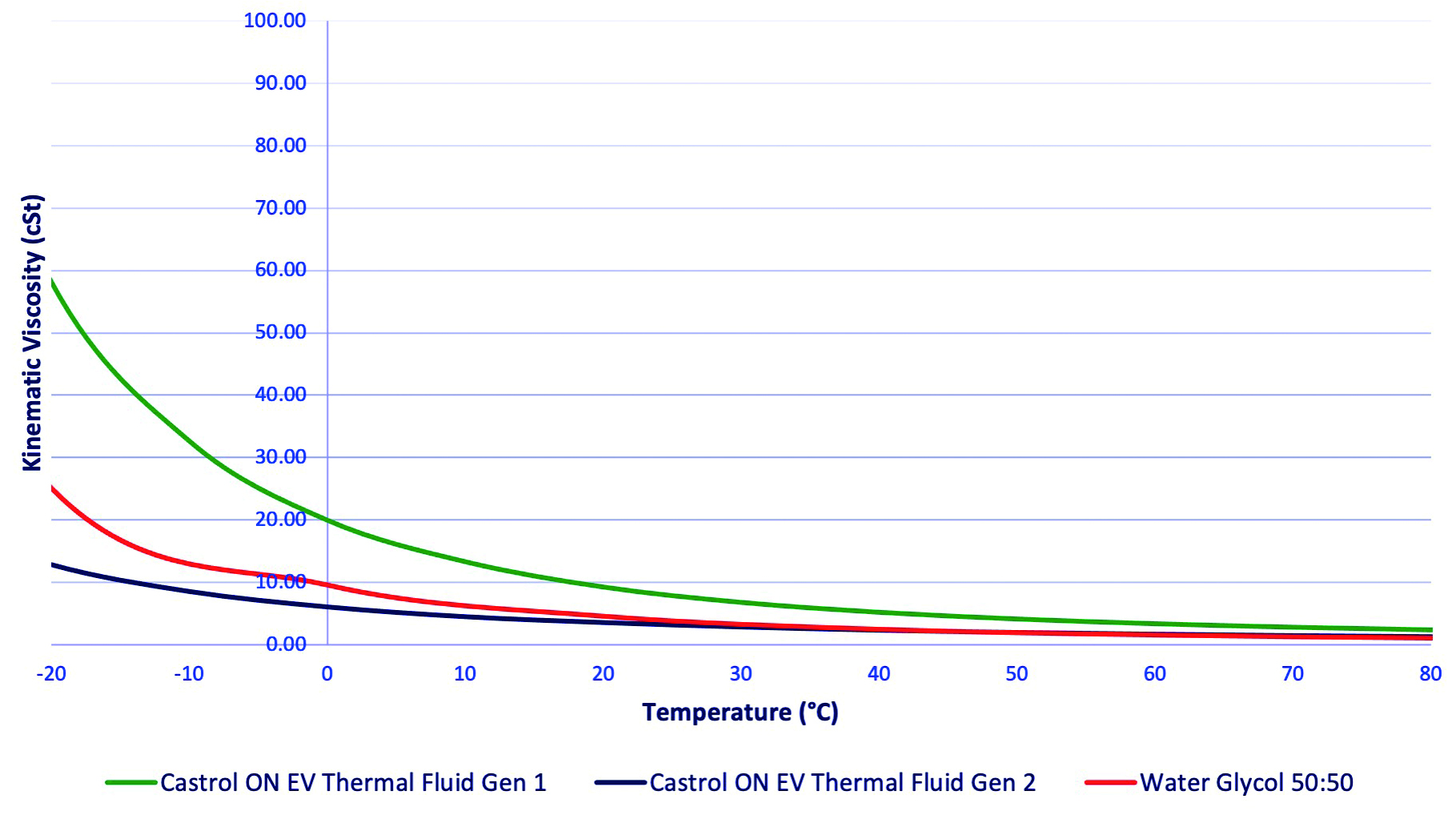

The general belief in the industry is that immersion fluids are much more viscous than water-glycol. That was true for the first generation of Castrol’s ON EV thermal fluids, which are successfully used by Castrol’s customers. However, Castrol continued to develop further fluids, resulting in Castrol’s second-generation immersion fluids, which exhibit similar viscosity to water-glycol fluids at 30°C – 2.9cSt compared with 2.7cSt for 50:50 water-glycol. This decrease in viscosity between the two generations of Castrol ON EV thermal fluid reduces the pump power required in an immersion-cooled battery system, thereby increasing efficiency.

Below 30°C the second-generation EV thermal fluid has even lower viscosity than water-glycol. That means that Castrol’s second-generation ON EV thermal fluids require similar or lower pumping power compared to water-glycol based systems, hence optimizing the efficiency and effectiveness of the temperature-management process.

Analysis in Graz focused on identifying the optimal cell cooling solution, including whether it is better to have an increased cooling area but lower thermal properties of the fluid with immersion cooling, or a lower cooling area and higher fluid thermal properties with indirect cooling. In addition Virtual Vehicle looked at the extra benefits that can be derived from cooling busbars – how the thermal environment affects the electrical performance and aging of the cells, and whether fluid flashpoint is related to safety performance.

To support this research, immersion and indirect minimodules were designed and constructed with seven nickel-cobalt-aluminum (NCA) 21700 cylindrical cells. The immersion-cooled minimodule used direct busbar cooling and was designed and optimized with computational fluid dynamics (CFD) for heat transfer and minimized pressure drop. The minimodules were then put through performance and durability testing to analyze thermal and electrical behavior, as well as being subjected to thermal propagation testing. Performance and durability test conditions were created to replicate realistic fast-charging scenarios, representing a 10-90% charge at a 3C charging rate, equivalent to just under 20 minutes of charge time.

Performance analysis found that immersion cooling improved the thermal gradient and peak temperature of cells under fast charging, with the second-generation Castrol ON EV thermal fluid minimizing the surface cell thermal gradient to under 1.5°C.

Evaluation of durability identified that immersion cooling can extract more performance from cells. While the immersion-cooled module received 25% higher capacity through constant current charging than the indirectly cooled module, it had a 16% lower degradation rate despite the higher electrical stress. Significantly, Castrol and Virtual Vehicle expect this difference to increase alongside an increase in charge rate.

To gauge the safety of the immersion and indirectly cooled systems, Castrol and Virtual Vehicle designed a series of thermal runaway tests. These tests were performed in a sealed chamber with limited oxygen to enable the observation of any failure, as well as to ensure that the module was not fully destroyed.

A nail penetration method was used to initiate the thermal runaway of the central cell. Thermal runaway can lead to thermal propagation, where heat from a damaged cell is transferred via convection and conduction to adjacent cells, a process that can potentially lead to catastrophic failure of the entire battery pack.

During testing, the indirect minimodule caught fire and continued to burn until the oxygen had been depleted in the test chamber. If there had been sufficient oxygen it is highly likely that the whole module would have been destroyed. By contrast, the immersion-cooled module proved effective in mitigating thermal propagation even though it was not optimized for safety. Heat dissipation and not the flashpoint of the fluid determines safety in immersion-cooled systems. Effective heat dissipation is a combination of vent-gas management and the fluid conducting heat away from the damaged cell.

and post-test

Castrol ON EV thermal fluids are developed to help avoid the risk of thermal propagation by directly cooling the individual cells, where high temperatures can cause irreversible failure as a result of overcharging or short-circuiting. With immersion-cooled systems, thermal events of individual cells are better thermally managed. Therefore, if they occur they can be quenched at source – unlike in indirectly cooled systems.

In conclusion, analysis by Castrol and Virtual Vehicle emphasizes that immersion cooling through Castrol ON EV thermal fluids enables sustained ultrafast charging and thermal propagation mitigation. Compared with the indirect alternative, the immersion-cooling approach clearly displayed superior thermal performance in terms of peak temperatures, inter- and intra-cell gradients, and heat rejection.

In addition, extracting higher performance via immersion cooling does not come at the cost of capacity. The research suggests that in extrapolating the data to higher energy density cells and higher charging rates, the differences would become even more pronounced between immersion and indirect systems.

Castrol ON thermal fluid is part of a family of Castrol ON products, which include Castrol ON e-transmission fluids and Castrol ON e-greases. Castrol’s high-performance e-mobility team continues to optimize thermal management performance through joint co-engineering programs with partners, anticipating the multifaceted technical challenges resulting from increasing demands for greater battery and powertrain performance.