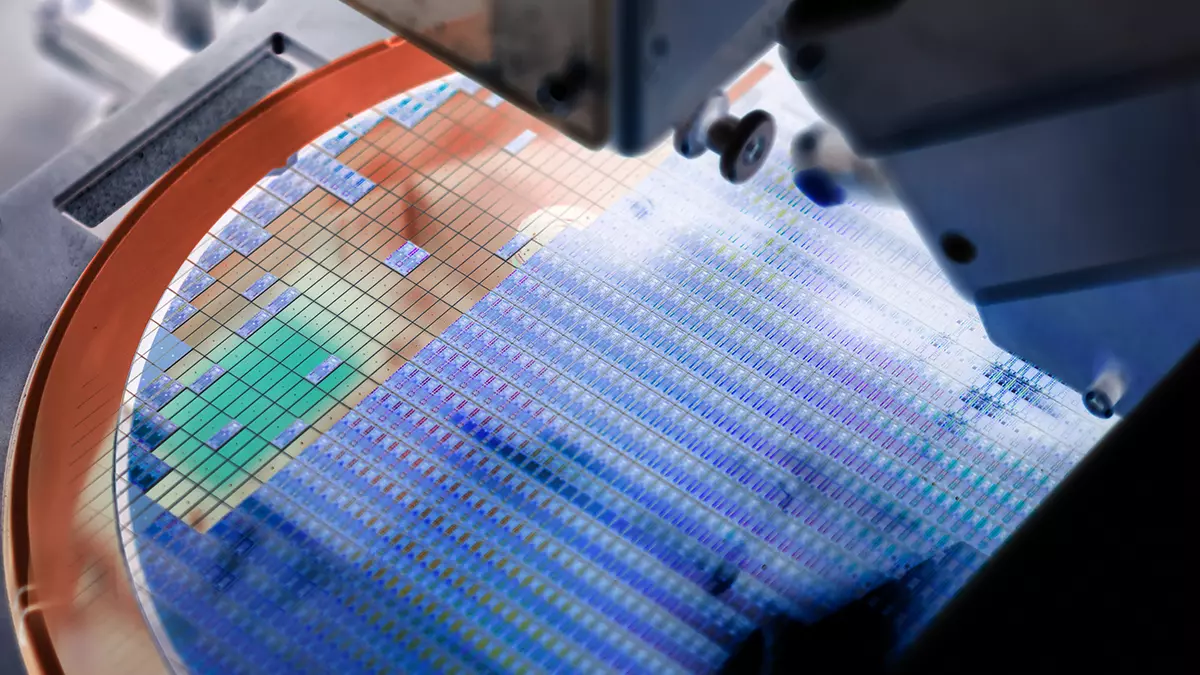

Based on multiple miniature e-beam columns, Multibeam’s maskless e-beam system opens up possibilities that haven’t been available in semiconductor manufacturing. By enabling rapid cycles of learning, the system allows:

- Chip designers to conduct wafer-scale experiments where they can customize every chip on the wafer to explore new ideas

- Design changes to be implemented immediately, without having to wait for new masks

- Rapid iterations between design feedback and validation

- Fast ramp to production once the design has been validated

The MEBL system also helps accelerate system-level optimization through advanced integration of chips. By enabling chip designers to utilize next-generation interposers, they will be able to pack more chips into each package, while achieving higher chip-to-chip bandwidth and lower energy per bit transfer – all crucial for producing AI chips.

Synopsys CATS software is a key component that enables advanced integration. Multibeam’s integration of CATS software highlights its versatility for maskless, as well as mask-based, chip production flows, allowing for seamless integration. The scalable CATS software suite transcribes complex chip design data into machine-readable instructions for e-beam, laser, and multi-beam mask writer machines. The software suite provides data prep modules for data fracture, data verification, mask rule checking, mask error correction, job deck processing, layer operations, and data sizing. It also integrates into Synopsys Proteus™ full-chip mask synthesis smart manufacturing solutions for correction, which enhances resolution for better yield and supports large-volume, high-throughput data transfer.

“One of Synopsys’ goals is to make it much easier and quicker for chip designers to bring their products to market with fewer mistakes and fewer cycles, and that’s one of the key benefits of our technology as well,” said Dr. Ken MacWilliams, President of Multibeam. “In addition, Synopsys brought e-beam expertise that complemented ours, as well as a mindset geared toward building a system that would work well in a production environment.”