One of the most successful systems in the DLP market, the Perfactory, has undergone a number of upgrades since it was launched over 20 years ago and its latest generation is setting a new standard in the industry. The ETEC Pro XL by Desktop Metal, delivers the same reliable printing experience that users have come to expect of the company’s DLP solutions, and comes with several updates and innovations, including the capacity to print finer details, a larger print volume, enhanced workflow optimization and faster printing. On top of that, at under $40,000, the new industrial system is available at a more cost efficient price point than its predecessor.

Tuned for precision curing

When EnvisionTEC first launched its Perfactory DLP system in 2002, the technology proved to be a game changer, giving users the ability to print high-resolution parts from photopolymer resins at significantly faster rates than stereolithography. This was (and is) due to the nature of DLP technology which, rather than employ a laser to selectively cure layers of resin, leverages a video projector to expose a light pattern onto resin, curing whole layers with a single exposure. Over the years, EnvisionTEC’s DLP process continued to evolve, with software and hardware advances which enabled opportunities for high precision applications, mass customization, indirect production and, thanks to the advancements in hardware and materials science, the manufacturing of fully isotropic industrial end-use parts.

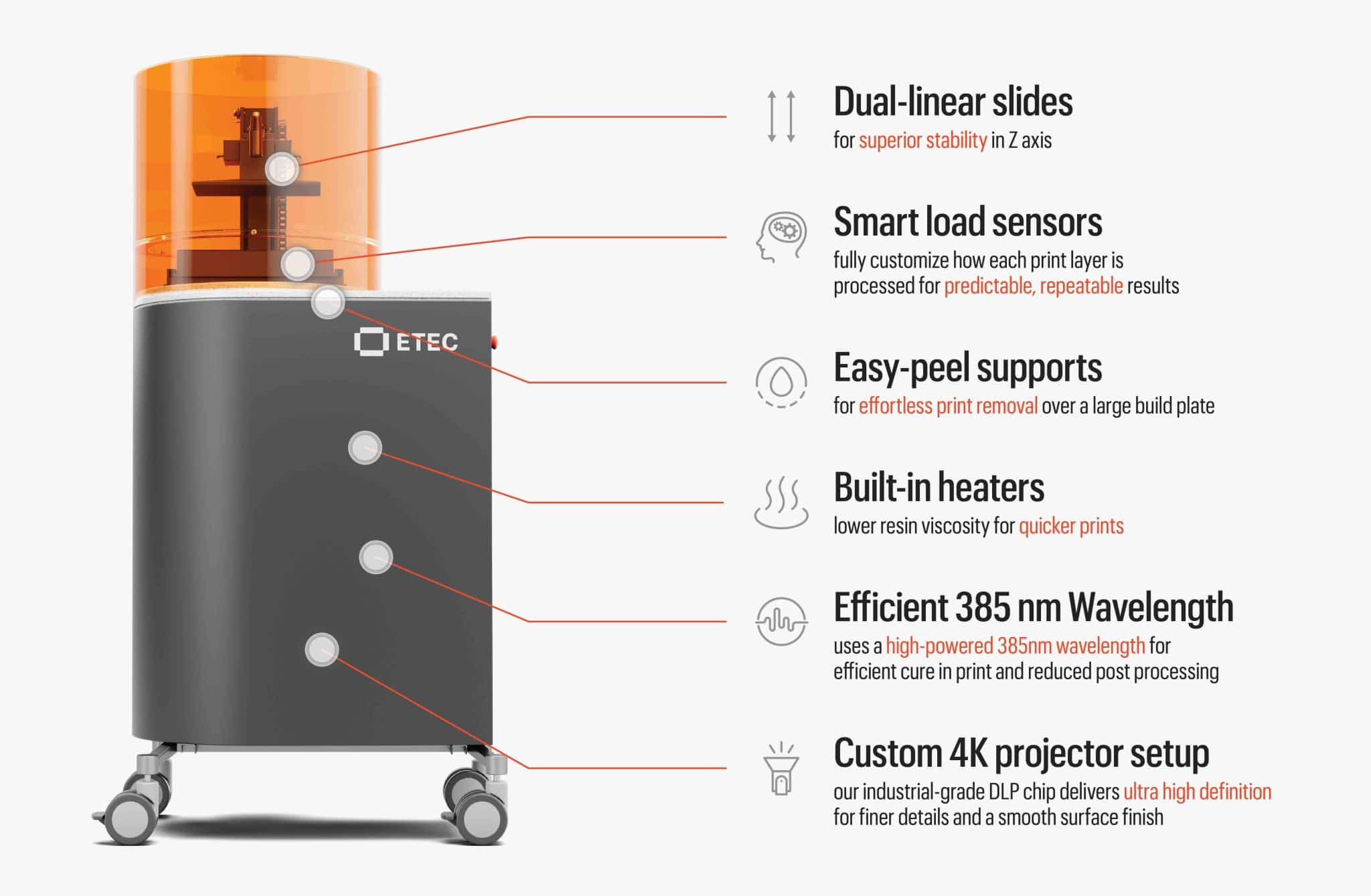

The ETEC Pro XL is the culmination of this evolution, featuring cutting-edge hardware and workflow-optimized software. The system itself is based on the same chassis design of the original Perfactory machine, but features a larger build volume of 249.1 x 140.1 x 165.1 mm and several other upgrades. Among these is a 4K UHD projector (3840 x 2160 pixel) powered by an high powered industrial DLP chip, which is positioned under the resin vat and exposes the entire build platform at once, enabling unparalleled throughput.

The system’s UV optics have been tuned to 385 nm wavelength, enabling complete translucent parts if desired, and are optimized for the least image distortion, resulting in accurate, high-resolution curing. This precision curing capability is also reinforced by the PRO XL’s patented pixel-shifting technology, which eliminates jagged edges along curved surfaces (caused by square-shaped pixels) by shifting pixels at the edge of layers in both X and Y directions. In terms of resolution, the ETEC Pro XL has a native XY resolution of 65 μm and Z resolution of 25, 50 or 100 μm.

Going into Hyperprint

Going into Hyperprint

The new ETEC Pro XL also integrates the innovative Hyperprint Technology, the latest innovation by Desktop Metal to promote rapid, continuous printing. This technology marks a new era for DLP, which can achieve continuous printing without the need for an oxygen layer. The use of oxygen had been the standard at EnvisionTEC since 2016 when it launched its CDLM process, which used a layer of oxygen and an oxygen-permeable film on the bottom of the resin tray to facilitate the separation of each cured layer from the build tray resulting in a faster printing process. While effective, the use of oxygen requires the use of additional equipment, such as oxygen tanks or condensing systems, which add cost and come with safety considerations.

Hyperprint technology overcomes this by using heat to decrease the viscosity of the resin, which increases processability, thus speeding up material recoating. The process also integrates Closed Loop Printing load sensors, which automatically detect when the cured resin layer has separated from the resin vat film, letting the 3D printer reposition the build plate using dual linear slides as soon as the layer is separated. This saves time for every layer compared to pre-programmed layer separation estimates, which can add up significantly. Hyperprint technology was first launched in 2021 on the Desktop Health Einstein printer and is now also available on the ETEC Pro XL platform.

From castable resins to engineering-grade photopolymers

As the DLP process has advanced so too have photopolymers compatible with the technology. The ETEC Pro XL can be used with a wide range of curable resins, including proprietary ETEC resins and third-party materials from leading materials suppliers. The current available range of qualified third-party materials for the platform includes Henkel LOCTITE 3D 3843, a transparent resin with properties similar to ABS and a heat deflection temperature (HDT) of 60°C; LOCTITE 3D IND 405, a high-strength engineering polymer with good impact resistance; Evonik INFINAM ST 6100 L, a high-strength photopolymer with HDT of 120°C; and BASF Ultracur3D RG 3280, a ceramic-filled resin with high stiffness and HDT B above 280°C.

ETEC also has several qualified materials from its own portfolio. These include: ETEC HTM 140, high-temperature molding material with HDT of 140°C; ETEC E-Rigid Form Charcoal, polyurethane-like resin characterized by its high strength and stiffness; ETEC Easy Cast 2.0, a high-wax casting material for jewelry applications; and ETEC PIC 100, a casting resin with excellent burnout properties. A number of revolutionary resins are also being validated for this system, launching in the coming months.

“Because the Pro XL is such a versatile production tool, we’ve tailored a material portfolio to meet the performance needs of a wide range of industrial applications,” Desktop Metal says of its DLP machine. “Targeting some of the best property sets available, our team of experts has developed innovative resins and we’ve qualified premium third-party materials that allow customers to embrace the benefits of 3D printing without sacrificing performance.”

The material versatility is also enhanced by an integrated material heating system in the 3D printer, which heats resin to temperatures of up to 45°C throughout the printing process to maintain low viscosity. This has the benefit of facilitating the recoating process resulting in reduced printing forces and faster printing rates.

Applications and use cases

The print speed, high-resolution capabilities and vast material compatibility of the ETEC Pro XL ultimately make for a highly versatile DLP system capable of fulfilling applications in many industries, including aerospace, automotive, healthcare, industrial manufacturing, luxury goods and more. Desktop Metal has highlighted several possible applications for its new system, from automotive and machine parts, to microfluidic devices and fluid ducts, to housings, jigs and fixtures, to castable jewelry patterns and beyond.

In terms of throughput, the machine is equipped for anything from rapid prototyping to volume production. The machine also allows for seamless scaling to mass production on the ETEC Xtreme 8K system—the largest production-grade DLP 3D printer—since both operate within the same ecosystem. The Pro XL system is also designed to run 24/7 within minimal intervention, thanks to features like automated job completion alerts and job queuing, as well as swappable build plates.

At SARL Mecamarne, a general mechanics company based out of Mardeuil, France, engineers are leveraging the technology to produce tooling and machine components to streamline the production chain and minimize downtimes for machines. Among the parts they have made using the ETEC Pro XL are clamping tabs, which are traditionally made from metal. By leveraging engineering-grade polymers and the DLP system, Mecamarne has successfully accelerated production while also minimizing costs. The general mechanics company has also successfully 3D printed tooling pieces used in bottling production chains. This application is another example of how the ETEC Pro XL can be used for metal replacement.

Ultimately, the ETEC Pro XL by Desktop Metal is a versatile system that progresses the legacy of EnvisionTEC’s standard-setting Perfactory platform. As Ric Fulop, CEO and co-founder of Desktop Metal, says: “Our ETEC polymer brand has been a leader for 20+ years in high-quality DLP printing, and the ETC Pro XL continues that legacy at an accessible new price point while delivering critical user upgrades.”