Right now is a pivotal time for Japanese makers. Policies like the US Inflation Reduction Act are forcing corporations to diversify their supply chains for reliability and to reduce country risks, with nations such as China. Japan is known for its reliability, advanced technology, and a weak JPY, so for the time being Japan has never been a more cost-effective option. This means that Japanese firms have an opportunity to expand their existing global market shares. Do you agree with this sentiment, and in your opinion, what do you believe to be the advantages of Japanese companies in this current macroeconomic environment?

First of all, I would agree with your premise, and by utilizing the current situation with the macroeconomic environment we can grow our sales and profits. In terms of the strengths of Japanese manufacturers, as you mentioned, quality is one of the strengths. We are also able to keep up with the promises and commitments we have made to customers and partners.

Following these concepts is the idea that Japan’s population is declining severely. It has been declining since 2008 and it is expected to drop below 100 million by around 2050. For industries here in Japan it presents a series of challenges including a labor crisis and a shrinking domestic market to sell products. How is your company responding to this demographic shift and what systems have you put in place to ensure your longevity?

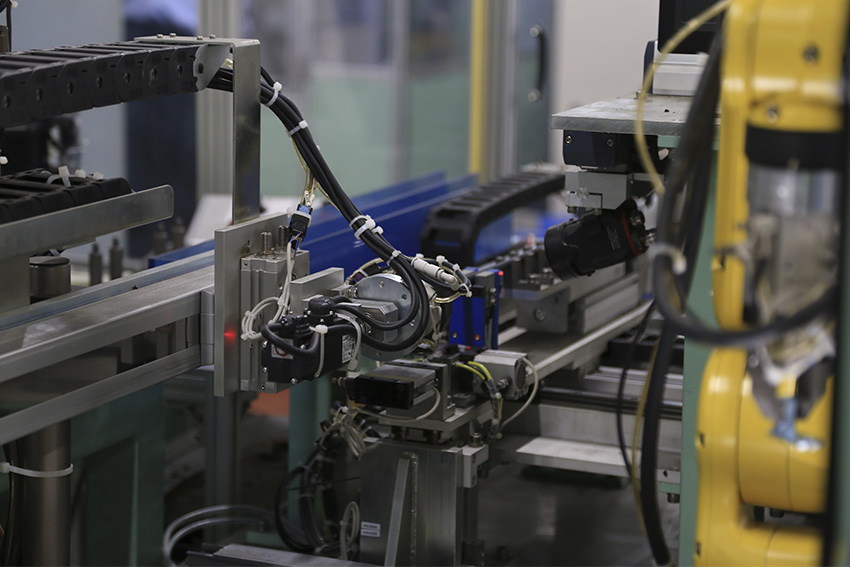

Regarding the declining population, we are replacing some of the production process steps with automated systems. We have been quite successful in the placement of these automated systems. The company has seen a decrease in the number of full-time employees since I joined the company so therefore automated systems to mitigate that loss are important.

Although the population is decreasing in Japan, the populations of Asian countries like India and Indonesia are booming. To this end, we are establishing subsidiaries in ASEAN countries where the population is increasing. In those countries, we also see the number of young people increasing which is a good thing for us because we supply parts for motorcycles. We are expanding production in such countries. In Japan, we are manufacturing parts that can be manufactured by automated systems, while in ASEAN countries we are concentrating on manufacturing and assembly processes that cannot be completed by automated systems.

Today the automotive industry is living in a time of incredible transformation, and with this experts claim there are three big trends. First is the move towards electrification, second is the change in the driving experience with the move towards autonomous driving, and thirdly there is a big change in terms of vehicle ownership. More and more we are seeing cars transitioning from automotive into more of a mobility device, with revenue models changing as a result. With these changes, there is no clear definition of how the industry will look in 10-15 years from now. In your opinion, how do you think the automotive and motorcycle market will evolve over the next decade?

I think over the next decade, on top of conventional automotive makers, we will start seeing new players in the industry, and a good example might be Tesla. However, these new players do not have sufficient capabilities to manufacture cars. I imagine that they will rely on component makers like our company. For us, we need to promote what we can do and what we can offer to them, especially for new EVs.

Regarding electrification we understand that there will no longer be a demand for fuel hoses, however, demand for brake hoses will remain. Some parts will become redundant but others will remain, and additionally, I’m sure we will start to see demand for new parts as well. In particular, we believe there will be an increasing demand for components related to battery cooling including hosing solutions. This is an area we are in active development in currently. Part of that process is identifying what components will remain once full transformation takes place and what will become redundant.

I purchased a Volvo vehicle because it has autonomous driving but honestly speaking, it is terrifying.

2023 was an extraordinary year in many aspects. We saw a big slowdown in EV sales, but simultaneously we saw hybrids have their best year of record. This was clear when you looked at the earnings performances of large Japanese companies. You had a great financial year, Toyota performed above expectations, Denso had a great, and many others too. Over the next 12 months, how do you anticipate the market to move? Do you think we are going to see big changes in the trends we saw last year or do you think it is going to remain the same?

I think for the next 12 months we will continue to see a trend where hybrid vehicles continue to sell well. If I look at my wife as an example, she only drives about 10km per day so in her case it would be suitable, however, the infrastructure for EVs is not yet ready. I live in an apartment and there was once a discussion about installing a battery charger for the apartment but the idea was rejected by the residents of the building. Mentality needs to also catch up with the innovations being made in electrification. I think that the lack of infrastructure along with the mentality of Japanese people will be a hindrance for EVs.

My son lives in Tokyo and he has a rental car membership. When he goes to a parking lot he can easily borrow an EV for around JPY 3,000 for several hours. If you live in an urban center it is more beneficial economically to just borrow a car instead. In rural areas, however, it is much more difficult to get by on this model.

Piping systems must be able to withstand very challenging environments, and on top of the high heat temperatures and high pressure, they must also deal with mechanical stress as well as vibrations. With today’s modern cars, they also need to be very lightweight to reduce drag while maintaining structural integrity. Could you give us an insight into your R&D and the kind of testing that you do to ensure you’re able to meet these very high demands of OEMs?

Our new product that focuses on braking is thinner than conventional braking hoses. This contributes greatly to reducing the weight of certain vehicles. We are now attempting to replace all of our conventional materials with resins to reduce weight.

The company has always taken the stance of creating products that are added-value. In particular, for battery cooling systems, lighter resin is required and that will suffer less vibrations. Additionally, by having a lighter material the vehicle will be more energy efficient, which in turn will contribute to the duration of the battery.

One thing we have noticed is that consumers are demanding more traceability and transparency in the products they purchase. Even with automobiles this is becoming a factor, and your company has the option to use recycled materials as well as plant-based resins. Could you comment on the use of these alternative and sustainable materials for your business?

We would like to pursue the application of plant-based resins and plastics going forward, but we haven’t yet determined the direction or how to use the plastic. We are looking to move away from oil-based plastics and transition over to more sustainable materials. We can’t develop the plastic itself but we are considering how we can process plant-based plastics.

We saw in our research that your company had diversified into other business fields such as the housing sector, laser markers, and factory monitoring systems, fields that are very different from your usual automotive and motorcycle segments. Why did you choose to diversify into these sectors and looking at the future, are there any new applications that you think you could target?

To be completely honest with you, those moves were driven by an element of desperation. When I joined this company in 1993 we were producing power steering hoses which was mainstream production, but to be electrified, we were told that power steering hoses would no longer be needed. We needed to find something else to produce, and in this kind of desperate situation, we developed hoses for water tap systems. In fact, at this moment almost all hoses used for TOTO’s washlet systems are provided by us. This washlet system isn’t very prevalent in the global market so you won’t find it in the US or Europe but you might find it in China or South Korea.

One of the historical aspects of your business is power steering hosing, but as the industry moves towards full electrification this is one of many components that probably won’t be needed anymore. When you look at the future of EV architecture, what type of products and demands do you think your company can cater to?

EVs are essentially becoming a bigger version of mobile phones, meaning that almost all the functionality of a mobile phone is now being incorporated into cars and that even includes a camera. That also means that almost all the components of a mobile phone will apply to EVs. We also have to consider how autonomous driving systems will evolve. This might result in back and side mirrors no longer being needed since they will be replaced by cameras, which presents more demand for camera components.

Engines will be replaced by motors and then there will be a need for larger batteries. Those batteries will generate a lot of heat, so to prolong the life of those batteries adequate cooling solutions are necessary. I believe that we will see more components that will function to control temperature. We are considering developing products that focus on them.

If we fast forward even further into the future, I believe that people will be able to just press one button and a drone will quickly come to pick the passenger up and take them where they want to go. I’m not sure what will happen to conventional cars in such a future.

One of the best aspects of mechanical cars is the tangible feel of the road through the steering wheel and the brakes. EVs incorporate electric brake systems and the new Tesla Cyber Truck uses a steer-by-wire system, allowing just half a turn to pull off a U-turn. For some, the passion of the car is lost in these technologies. What is your take on that, do you feel the same way? Do you feel there is still room for older automotive technology?

I hope that in the future there is a switch where you can move between mechanical and non-mechanical. Although vehicles are being electrified, I think that certain things will remain mechanical such as hydraulic systems. The good thing about hydraulic systems is that you can feel the car moving up and down, and it isn’t a black-and-white feeling.

Earlier you mentioned battery cooling and temperature control systems. To develop these new products are you currently looking for any partnerships? If so, what does a partner of choice look like?

We already have a partner in India. As you are probably aware, Japanese people are typically quite prudent, and the same goes for Japanese car makers. Even if we propose new technology to car makers they don’t adopt it, particularly when they ask about real-world examples. When you go back to the time when Sony invented the Walkman, that kind of idea was easily adopted, but recently a lot of companies have been afraid of failure and therefore refuse to take any risks on new technologies or products. This is why we looked overseas for partners, and we believe that the overseas markets are much more receptive to new technologies. Once we create real-world examples we can then take that back to Japanese car makers. This is why overseas partners are very important to us right now.

We understand from our research that you have a presence in all major continents, and recently you expanded to Bulgaria in 2022. Could you give us a brief overview of why you’ve chosen such varied strategic locations, and moving forward, what new locations do you foresee having the most potential in the future?

To seek global opportunities, we opened our plant in the United States, and this realistically came due to their need to cater to demand in this market. The same goes for Asian countries where we have a presence. I have lived overseas for about 25 years of my life, and when I was in the UK I felt that Nichirin could not survive by only catering to Japanese companies. I felt that we needed to further develop our presence in varied markets. This is where I began promoting our products to Western makers, but by only bringing Japanese products I was not successful in doing so. Around that time a French company called Hutchinson approached us with the proposition that we purchase their department for brake hoses which included a factory. This was a great opportunity since if we purchased this factory we would have a direct channel to Western companies, with the factory being located in Spain. Because labor costs were high in Spain we outsourced production to Bulgaria.

We approached Western companies because we understand that the Japanese domestic market will not grow any further because of the population decline. Ten years ago we had 0% foreign sales but now we have about 8% of our sales coming from foreign companies. I think it was a good decision to expand to those Western countries. This year we will receive orders from BMW, so there are exciting times ahead. The next goal as CEO is to attempt to enter the African market.

Imagine that we came back on the last day of your presidency and had this interview all over again. What goals or dreams would you like to achieve by the time you are ready to hand the baton onto the next generation of Nichirin executives?

I am now the 14th president of this company, and I don’t have an objection to inviting a non-Japanese person to become the next-generation president. I would also like to establish an equal ratio of male-to-female employees in the company during my presidency. Looking at the new hires, it is now almost 50-50 with the number of non-Japanese workers to Japanese workers. The company is working towards a future that is truly diversified, regardless of age, gender, or nationality.

For more details, explore their website at https://www.nichirin.co.jp/