Seaweed Day starts at 8am. Haunted by pervasive news that so many of our everyday habits harm our planet, I wonder how to minimize my personal use of plastics. I embark upon a day of replacing the microplastics that pollute our atmosphere, our water and even our bloodstreams.

How much of my daily life can I accomplish with seaweed? Eating, washing, dressing? Armed with a budget of $500, I set out on a seaweed-based product shopping spree.

“Seaweed” refers to thousands of algae species; kelp is the largest subgroup. Scientists and entrepreneurs are exploring its seemingly limitless potential. Sometime in the future, they tell us, it will be a commonly used biofuel or supplant ubiquitous plastics, which wrap our food and weave through our clothing fibers. Seaweed cultivation has a long history in Asia, but more American and European companies are recognizing how a plant that requires little more than sunlight and seawater could change the course of many industries.

I’m all in to find out how seaweed can alter my everyday, from fashion and food to all other daily necessities.

But I’m already behind. Seaweed linens exist theoretically but not readily; they’re still in prototype stage. My search for seaweed toilet paper also proves fruitless.

It gets easier. My toothpaste uses carrageenan, a red seaweed used in processed foods and toiletries as a binding agent. Seaweed soap? Check. Seaweed shampoo? Check.

Seaweed towel to dry myself? I commit my second violation with a cotton towel.

Then there’s clothing. “What are you wearing?” Natalia Burakowska, co-founder of the sustainable clothing line Terratela, asks me over the phone.

“My favorite sweatshirt,” I respond.

“No one ever answers with material. It’s always a brand or where they bought it,” she says. I rip off my sweatshirt and peer at the label. 50% polyester, 50% cotton.

“Every piece of polyester clothing made still exists,” says Burakowska. Natural elements blended with polyester fiber degrade, leaving synthetic skeletons. Polyester can take up to 200 years to truly degrade, and as it was invented in the mid-1930s, we’re still stuck with its original iterations.

Buttery soft but strong, Terratela’s seaweed T-shirt is a seemingly miraculous union of food and fiber. One day, could fabric made of seaweed like the large-frond variety Icelandic knotted wrack eradicate polyester?

“Icelandic knotted wrack, like your front lawn, must be trimmed so it remains healthy and under control. We’re trying to avoid cotton and use less water-intensive fibers,” she answers.

Those T-shirts are made from 39% or less SeaCell fiber, itself made from about 19% Icelandic knotted wrack. The rest comes from beech and eucalyptus, trees that require little water.

“People get upset about the percentage of biomaterials in this clothing, but think about the amount of plastic you’re putting on your body. We need to start somewhere,” she explains.

SeaCell is not without controversy – some clothing by other manufacturers had been labeled as containing it but in fact had none – so Burakowska personally examines her entire supply chain, visiting Portuguese garment manufacturers and Icelandic seaweed producers.

Once upon a time before industrialization, clothes were recognizably agricultural products. Food and fashion came from the same fields. Though the industries have diverged, they’ve followed similar trajectories. “By the time food or clothing reaches you, a hundred people have touched it,” says Burakowska, who seeks a single solution to both industries’ problems.

Later, I press Sabbatical Beauty’s Marine Serum into my face and flick kelp-infused mascara onto my eyelashes.

“Seaweed is high in antioxidants, which helps with regenerating skin,” says the Sabbatical Beauty founder, Adeline Koh. The formulation contains more seaweed, such as fermented kelp and wakame, than a typical product (my mascara lists kelp as the 16th of 20 ingredients).

None of these products’ packaging contain seaweed, though seaweed packaging exists. More violations.

I asked Alyssa Pace, the communications lead at Sway, which makes packaging film to replace the clear plastic windows that allow us to see products. “When can I go to my corner store and buy something wrapped in Sway?” I ask.

“Maybe five years from now, you’ll see Sway on grocery store shelves,” she says. The company’s flagship bioplastic film is currently geared toward fashion and home goods. “In our film, we don’t use any petroleum-based inputs. It’s disintegrating entirely. There are no microplastics.”

I forgo my usual coffee for Cup of Sea’s sea smoke tea, which blends Maine bladderwrack with lapsang souchong. It is packed loose since tea bags can leach microplastics into tea.

Breakfast consists of Gimme Seaweed’s roasted seaweed snacks and a smoothie whipped from Atlantic Sea Farms’ frozen blueberry-ginger-kelp cubes, which are pleasingly spicy and slippery – like a seaweed salad you’d get with your sushi, minus the salt. My chihuahua, Coconut, gets a sprinkle of Norwegian kelp “dogzymes” on her breakfast.

I check in with Jessica Ball, a registered dietitian and the nutrition editor at EatingWell, to ensure I don’t overdose on seaweed. She assures me: “Seaweed is super nutritious and a great source of vitamins and essential minerals.” Ball recommends 4g to 5g, or about two sheets of nori per day and says “seaweed can also absorb potentially toxic metals like arsenic, mercury, aluminum and lead, if present”.

I put on my Terratela T-shirt (39% SeaCell, $95 – a price tag comparable to a designer T-shirt and requiring as much care: avoid putting it in the dryer) and Esme underpants (23% SeaCell, $26).

“I was looking for the highest percentage of SeaCell – there was one that was 100% but it didn’t hold up,” says Esme’s founder, Katherine Jacobson, whose line is also produced in Portugal, an epicenter of eco-friendly clothing manufacturers.

Weeks of research did not yield seaweed pants, so this would be a work-from-home Seaweed Day. Seaweed shoes are a not-quite-yet.

I would pair my imaginary seaweed pants with Oliver Charles’s SeaCell sweaters ($165). “SeaCell, on its own, is so smooth it feels like medical material,” says Slater McLean, the co-founder of the 3D knitwear brand. Their SeaCell sweater needs to be blended with organic cotton “to give it loft”. It’s a summer garment – and it’s winter in New York, so I’d still be a little cold.

To pass the time, I crochet Coconut a sweater with Hoooked yarn (20% SeaCell), indistinguishable from cotton, which constitutes the other 80% of the yarn. There will soon be more fiber with higher seaweed content. Keel Labs’ Kelsun, akin to ultra-fine muslin, is more than 70% seaweed-derived. Unlike SeaCell, Kelsun is not cellulosic, or, consisting of wood-derived vegetable fibers. Kelsun dresses debuted at Stella McCartney’s Paris Fashion Week show this year.

Lunch is air-fried and delicious. Andrew Wilkinson, the research chef at North Coast Seafoods, became aware of kelp’s sustainability and developed “meat” balls using sugar kelp, brown rice, green chickpeas and pea protein. North Coast Seafoods is a fresh fish distributor, but, he says: “I saw people making kelp into condiments. Kelp makes the ocean cleaner. It’s good for you, it tastes good. It needed to be a center-of-the-plate item.”

Atlantic Sea Farms produces kelp with a network of partner farmers. The Gulf of Maine is warming faster than any other body of water, and there is a need to diversify fishers’ income. Atlantic Sea Farms’ brand manager, Kiera Foti, explains how they assist fishermen in farming kelp where they normally fish, 7ft below the water’s surface. “We give them all the seed for kelp for free, help them with their first season, monitoring growth,” she says. After five to six months of growing time, “sprouts on those lines grow efficiently into 12ft-long blades. It’s a zero-input crop. It’s incredibly regenerative, absorbing excess carbon and nitrogen in the water.” The company also processes the kelp.

Last year, Atlantic Sea Farms says it represented the majority of the seaweed farmed in the US. But the company isn’t looking to follow in the footsteps of land agriculture. “We have not set up a large monoculture seaweed farming system,” says Foit. “We’ve developed small family farms of kelp.”

For dinner, I take some liberties. My steelhead trout was fed with Veramaris algae oil, which “reduces the need for wild foraged fish meal and oil, leaving ecosystems more intact and enhancing the omega-3 content of our fish”, says Todd English, the director of sustainability at Riverence.

Beef can also fit Seaweed Day rules, as Synergraze has developed technology that adds seaweed to cattle feed, reducing the amount of methane cows burp out by up to 90%.

After dinner, I sip a Nordés gin martini. “The most important botanical that we use is salicornia, which grows wild along the Galician coast. It brings saltiness and freshness,” says Francisco Fernandez Paez, the company’s North American area manager.

What if I had ordered takeout for dinner, delivered in “plastic-free” biodegradable containers?

Aqueous coatings penetrate fibers of cardboard containers, rendering them impervious to grease and moisture; “aqueous” or “dispersion” refers to the waterborne process by which microplastics are applied to cardboard.

Pierre Paslier co-founded Notpla, which develops seaweed-based alternatives to everyday items, from food containers to golf tees. He says that recycling such materials is misleading; well-intentioned consumers don’t know “when you recycle dispersion cardboard, microplastics go into water and it’s impossible to filter them out”.

Researching seaweed products has changed how I conduct everyday life. I search for composition tags on clothing, wonder how many times I’ve washed a microplastic-leeching garment. I critique people’s clothes, my eyes scanning a sea of polyester fleeces and nylon puffers.

“We shouldn’t beat ourselves up because we aren’t doing things right. The vast majority of decisions aren’t ours anymore,” Paslier consoles me, sort of.

“You buy what’s on the market. That’s why we’re working so hard to make these innovations available. Otherwise, you’re just given what’s on the menu.”

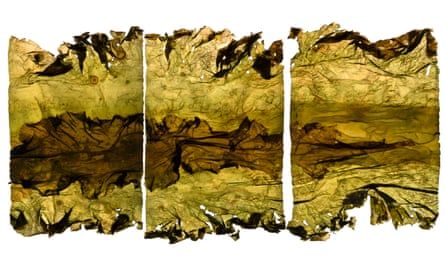

Seaweed photos by Josie Iselin, a photographer, author and designer of many books, with her last few focusing on the world of seaweeds and kelp. She is the co-director of a collaborative known as Above/Below, working to bring the recognition afforded the forests on land to the kelp forests below the ocean’s surface.

-

This article was amended on 15 December 2023. In an earlier version we said Atlantic Sea Farms “produces sugar kelp”; in fact the company grows a variety of kelps. The article had also previously quoted the spokesperson for Atlantic Sea Farms saying the kelp sprouts grow to 12ft-long in “four months”, and that the company’s output last year represented “70% of the seaweed farmed in the US”; the company told us after publication that the growing time is five to six months, and that it claims “the majority”, rather than 70%, of seaweed farmed in the US last year.