The global demand for protein is increasing rapidly, driven by population growth and evolving dietary recommendations, particularly in the BRICS countries (Brazil, Russia, India, China, and South Africa). This surge in demand is likely to result in a significant shortfall of protein for both human consumption and animal feed in the near future.

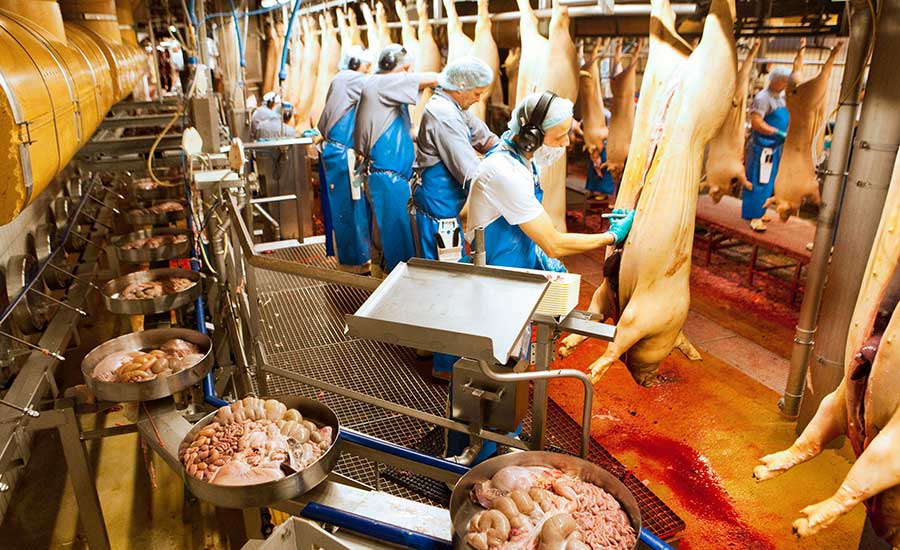

One promising solution lies in the efficient use of byproducts from the meat industry, such as liver, lungs, heart, kidney, spleen, and blood, which are rich in protein but often underutilized. This article explores the potential of these byproducts, their nutritional value, the processes needed to ensure their safety and shelf life, and methods of protein extraction that align with economic and environmental sustainability goals.

Nutritional Value and Potential of Byproducts

Animal byproducts make up about 10 percent of the live weight of animals and are an excellent source of low-fat protein. Despite this, the consumption of these byproducts has significantly decreased in Western Europe over the past few decades, leading to a surplus that is often relegated to low-value uses such as biogas production, fertilizer, or animal feed. Given their high protein content, especially in liver and blood (Table 1), these byproducts could play a crucial role in addressing global protein shortages. However, to make them suitable for human consumption, proper handling and processing are essential.

TABLE 1. Nutritional Composition of Byproducts

Ensuring Quality Through Optimal Handling and Cooling

For byproducts to be utilized effectively in human nutrition, they must be handled and cooled correctly immediately after slaughter. The essence of ensuring a long shelf life lies in adhering to three critical control points: temperature, time, and packaging.

- Temperature: Keeping byproducts as cold as possible is crucial to inhibit bacterial growth and extend shelf life.

- Time: Reducing the time between slaughter and cooling minimizes the risk of spoilage.

- Packaging: While packaging may not always be necessary before protein extraction, materials with low oxygen transmission rates can help prolong shelf life by limiting oxygen availability.

At Danish slaughterhouses, methods like quick chill and gyro cooling are employed to rapidly reduce the temperature of byproducts. In the quick chill method, products are exposed to supercooled air (–10 °C to –30 °C) with rapid circulation for a set time, followed by an equalization period. Gyro cooling, performed at slightly higher temperatures, involves placing products on conveyor belts designed in a spiral shape to save space (Figure 1). These methods ensure that byproducts reach the desired final temperature (typically <3 °C1 for byproducts destined for human consumption) quickly and efficiently, preserving their quality and safety.

FIGURE 1. At Danish Slaughterhouses, Methods Like Gyro Cooling are Employed to Rapidly Reduce the Temperature of Byproducts

After packaging, the products are frozen in cold stores, which specialize in rapid freezing. This process usually takes place in freezing tunnels, where the core temperature of the products is brought down below –12 °C over the course of 36 hours. Following this process, the products are stored at –18 °C.

Predictive Modeling for Shelf Life

Accurately determining the shelf life of byproducts is essential for their optimal use. Mathematical models provide valuable tools for predicting shelf life, based on factors such as initial bacterial count and storage conditions. The Danish Meat Research Institute (DMRI) has developed new models specifically for the byproducts heart, liver, and diaphragm, stored either chilled at 3°C or frozen at –18°C. These models, based on extensive shelf life studies, can be accessed and used free of charge through the DMRI Predict website.2

Development of the Models

The new models can predict the shelf life of heart, liver, and diaphragm (with fat) stored chilled at 3 °C or frozen at –18 °C. The models are based on a series of shelf life studies conducted over the course of 3 years. The shelf life largely depends on how the slaughterhouses handle, chill, and freeze the products. These processes vary significantly between different slaughterhouses, and to ensure that the models account for these variations, byproducts were collected from several Danish slaughterhouses. After collection, the byproducts were transported (chilled or frozen) to DMRI for the shelf life studies. Upon arrival, the frozen products were immediately placed in the freezer for storage at –18 °C, while the fresh products were stored chilled at 3 °C under aerobic conditions in polystyrene foam boxes, covered with a plastic sheet. Temperature loggers were applied both during transport and through the entire shelf life study to ensure that the cold chain was unbroken.

Shelf Life of Chilled and Frozen Byproducts

The shelf life of refrigerated byproducts is limited by the growth of psychrotrophic spoilage bacteria, causing putrefaction. The shelf life of the byproducts has been assessed based on bacterial growth (psychrotrophic bacterial count), as well as sensory assessment (odor) conducted by a professional panel. The products were analyzed upon arrival at DMRI and intermittently until the byproducts were completely spoiled, meaning that the odor assessment average scored the byproduct as unacceptable.

For frozen byproducts, the shelf life is limited by oxidation, which can cause a rancid odor or unacceptable taste. To determine the shelf life of the frozen byproducts, the sensory panel assessed the products after 6 months of storage and continuously over a period of up to 27 months. All products were assessed uncooked after defrosting, where relevant quality parameters such as rancidity, off-odor, and discoloration were evaluated. Hearts and livers were also assessed after heat treatment (sous vide), where the quality parameters rancidity and off-flavor were evaluated. Finally, defrosted products were intermittently used as raw material in relevant meat products, including mortadella sausages, liver pâté, and pepperoni, to investigate whether quality changes in the raw material would affect the eating quality of the final product.

Output of the Models

The model output varies depending on whether the model for frozen or chilled storage is selected. For chilled storage at 3 °C, the output consists of two curves: bacterial growth (psychrotrophic) and sensory development in odor over time. The curves are generated based on the entered parameters for initial bacterial count and product type. For example, the time by which an unacceptable sensory score of 5 is reached corresponds to a shelf life of 9 days for the diaphragm stored at 3 °C with an initial bacterial count of 2.5 log CFU/g (Figure 2).

FIGURE 2. Predicted Sensory and Microbial Shelf Life of Diaphragm Stored at 3 °C

The results from the sensory assessment of frozen byproducts are presented in multiple ways: A table showing the predicted probability of deterioration of the byproducts in relation to a specific attribute (e.g., rancid odor); and graphs showing the intensity of attributes versus storage period. For example, the sensory prediction for quality deterioration of diaphragms shows that after 4 months of storage, significant quality deterioration occurs as the fat covering the diaphragm is oxidized (yellow/brown discoloration). After an additional three months of freezing, the diaphragm develops a rancid odor. When used in sausages after 17 months at –18 °C, a perceptible sensory difference is detectable compared to byproducts stored at –18 °C for only 7 days, regardless of the amount of diaphragm added to the recipe or whether spices were added to the sausage (Figure 3).

FIGURE 3. Probability of Quality Deterioration of Diaphragm Stored at –18 °C (–0.4 °F).

Note: The probability is determined using a paired t-test based on the following criteria: Deterioration is unlikely: P > 0.05, Deterioration may occur: 0.01 < P ≤ 0.05, Deterioration is likely: P ≤ 0.01.

Extraction and Purification of Protein

Given the short shelf life of animal byproducts, extracting protein from them is often the most practical approach. The optimal extraction method will depend on the desired qualities of the final protein product. Enzymatic hydrolysis using proteolytic enzymes (proteases) may be a suitable method if nutritional value and absorption are the primary goals. In this process, the protein is broken down into smaller peptides and amino acids, which are more easily absorbed in the body than whole proteins, as the body’s digestive enzymes will need to break down the protein before it can be absorbed. A drawback of enzymatic hydrolysis is that the functionality of the protein is reduced, thus affecting its value as an ingredient in a product.

For applications where functional value is important, gentler extraction methods involving slightly acidic or alkaline solutions at low temperatures can be used. These methods minimize protein denaturation and preserve functional properties. Sometimes the choice of method will depend not only on the goal for the end product, but also on the protein source. For example, when purifying protein from blood cells (Figure 4), it will be necessary to break down the hemoglobin complex extensively to release the heme iron, which is responsible for the generally undesirable dark color and metallic taste. In such a process, a more or less complete loss of functionality is inevitable, as a prerequisite for removing the heme iron is that the hemoglobin undergoes a certain degree of degradation. If it is important to preserve some degree of functionality, one solution may be to perform the hydrolysis with an amino acid-specific protease that purposefully breaks down the types of peptide bonds that bind the heme iron to the rest of the protein complex instead of using a broad-spectrum protease. This is a good example of how a deep understanding of the composition and chemistry of the raw material/byproduct is important to find the right treatment method to achieve the desired quality of the end product.

FIGURE 4. Typical Processing Steps for Extracting and Purifying Protein from Blood; Another Valuable Side Stream From This Process is Heme Iron

In addition to determining the nutritional and functional qualities of the protein product, the extraction method can also be decisive for the protein yield in the final product. Harsher treatments often give a higher yield than gentle treatments, but usually require higher costs for equipment, process additives, and operation.

Food Safety in Protein Extraction

Ensuring food safety during the extraction process is paramount. This involves stringent microbiological and chemical control measures to prevent contamination and ensure that the final product is safe for human consumption. The byproduct used as a raw material must be of food quality, and the entire process, from removal from the animal to the finished product, must take place within defined requirement specifications that take food safety into account. This applies to microbiological control as well as chemical control.

Microbiological Safety

Throughout the process, it must be ensured that raw materials, intermediate products, and finished products stay within certain set requirements, which are defined based on the raw material and the quality of the product, as well as the course of the process. Microbiologically, thresholds must be set and observed for the presence and growth of microbes, both in vegetative and spore form, in the product and any intermediate products. If microbiological growth is beyond the applicable requirements, there is a risk that certain microorganisms will generate dangerous toxins and cause product spoilage, thus rendering the product unsuitable for human consumption.

Chemical Safety

For most processes, processing and handling equipment will need to be cleaned periodically by clean in place (CIP) or another type of cleaning method. Regardless of method, cleaning must be conducted according to an established protocol suitable for the process in question, to prevent processing and handling equipment from contaminating the product during the process. The extent of cleaning should be determined based on the applicable raw material, processing, product, and the product’s use, and there should be systematic monitoring of the raw material and the microbiological status of the process system. Cleaning detergents, which are often corrosive or oxidizing, must be thoroughly rinsed off equipment that has product contact to prevent the detergent from ending up in the product during the process. It is recommended to rinse in demineralized, clean water and rinse until the conductivity of the outlet water is below a defined limit value that is close to the conductivity of pure demineralized water.

When extracting with acid or alkaline agents, the procedure for handling the agents in question must be followed, and it is recommended that the product is neutralized to a neutral pH before the final process step.

Safety of Enzyme Treatment

When using enzymes in the process, the handling guidelines for the enzymes in question must be complied with, and the operator must be trained in the handling of enzymes. After the enzyme treatment has been completed, the enzyme should be denatured, inactivated, or otherwise removed from the product to prevent the presence of active enzyme in the subsequent process steps or in the final product.

Importance of Processes for Food Safety

During the process itself, there may be process steps that have a positive effect on the microbiological status of the product. This could be temperatures or pH values that make the conditions for microbiological growth poor or even inactivate microorganisms, or it could be a filtration process where microorganisms and spores are retained due to the pore size of the filter. Such process steps can have a positive impact on food safety in the process and the product, thus making microbiological control easier to manage.

In gentle protein extraction, limits are often set for both thermal impact and pH. If the purpose of the extraction is to achieve a protein with specific physical properties, then care must be taken to avoid elevated temperatures or extreme pH values that could jeopardize the desired functionality. Therefore, during gentle extraction processes, paying special attention to the risk of microbial growth is pivotal. In these situations, microfiltration with subsequent diafiltration may be a good option to retain microorganisms and let the proteins pass through the membrane. Subsequently, in most cases, the protein product is concentrated by ultrafiltration, where salts, sugars, organic acids, and smaller peptides with limited functionality pass through the membrane (the permeate), while the larger functional proteins are concentrated in the retentate.

Conclusion

The potential to utilize byproducts from the meat industry as a significant source of protein is vast and largely untapped. With proper handling, cooling, and extraction processes, these byproducts can be transformed into valuable nutritional resources. The new predictive models developed by DMRI2 offer a robust framework for determining the shelf life of these products, ensuring that they are used efficiently and safely.

As the global demand for protein continues to rise, the meat industry has a unique opportunity to contribute to sustainable protein production by upcycling byproducts. This not only addresses protein shortages, but also aligns with environmental sustainability goals by reducing waste and maximizing the use of available resources. Through continued innovation and adherence to stringent safety standards, the industry can ensure that animal byproducts become a staple in the global protein supply chain, providing high-quality nutrition to meet the needs of a growing population.

In summary, the utilization of animal byproducts presents a multifaceted opportunity to enhance global food security, reduce environmental impact, and create economic benefits. The meat industry, by adopting proper handling, cooling, and extraction techniques, can play a pivotal role in this transformation. The development and application of predictive models for shelf life ensure that these resources are used to their fullest potential, maintaining safety and quality standards. The shift toward a more sustainable and efficient use of byproducts is not only a necessity, but also a strategic advantage that can drive the meat industry forward in a rapidly changing global food landscape. Embracing this approach will help meet the nutritional needs of a growing population while fostering a more sustainable and resilient food system.

Acknowledgment

This work was supported by the Danish Pork Levy, the Danish Beef Levy, and the Danish Agency for Education and Research.

References

- European Commission. “Regulation (EC) No 853/2004 of the European Parliament and of the Council of 29 April 2004 laying down specific hygiene rules for food of animal origin.” April 29, 2004. https://eur-lex.europa.eu/eli/reg/2004/853/oj.

- Danish Meat Research Institute (DMRI). “Welcome to DMRI Predict.” http://dmripredict.dk/.

Marchen Hviid, M.Sc. is a Senior Scientist at the Danish Meat Research Institute (DMRI) at the Danish Technological Institute (DTI) in Denmark.

Emma Bildsted Petersen, M.Sc. is a Section Manager at the Danish Meat Research Institute (DMRI) at the Danish Technological Institute (DTI) in Denmark.

Emil Rathsach Petersen, M.Sc. is a Bioresources Specialist at the Danish Technological Institute (DTI) in Denmark.

Gry Carl Terrell, M.Sc. is the Business Manager at the Danish Meat Research Institute (DMRI) at the Danish Technological Institute (DTI) in Denmark.