Indeed, McGrath sees pricing strategy becoming an art form, as brands grapple with shifting consumer spending habits and their own financial balancing act. “Consumers are being hit by increased costs across many categories, which could affect the share of wallet dedicated to apparel,” she says.

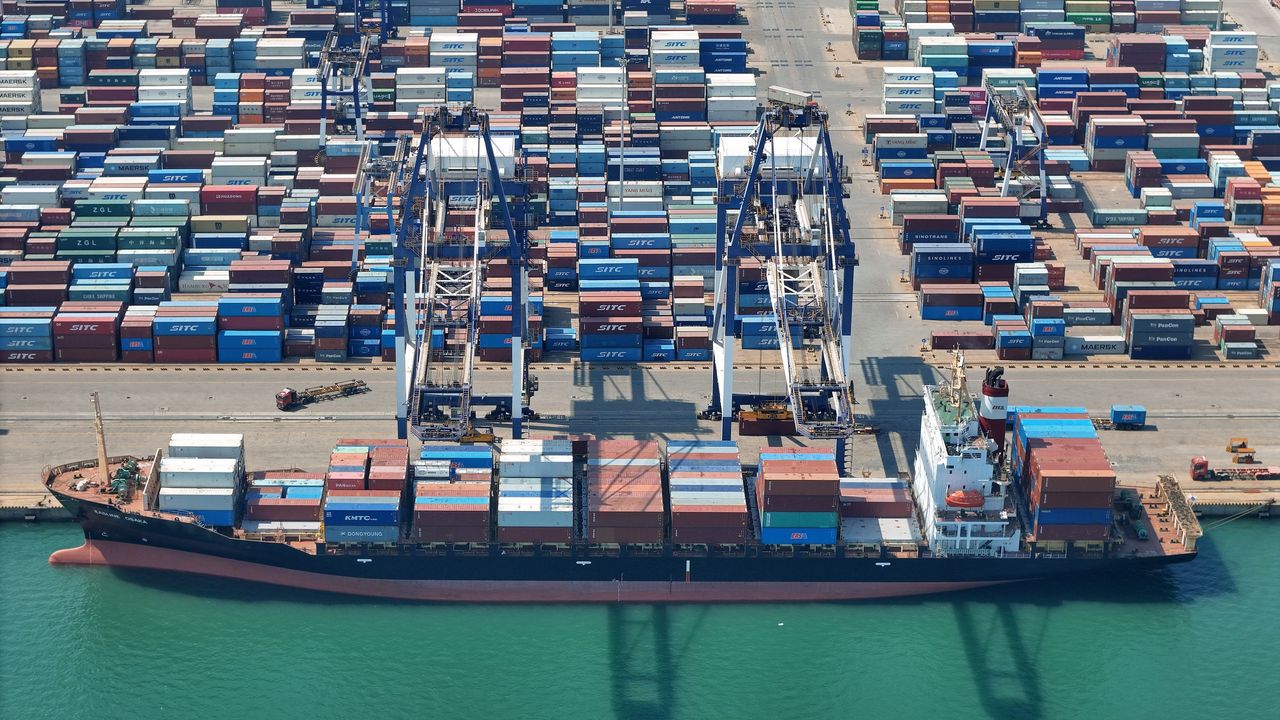

Undermining supply chain diversification

The unpredictability surrounding tariffs is stalling fashion’s efforts to reduce its dependence on China, Herman warns. Brands, uncertain about where trade policies will land, are hesitating on supply chain investments and hiring decisions. “There is a real concern that forthcoming announcements may generate more questions than answers,” he adds.

This uncertainty is particularly acute given Trump’s history of renegotiating and then disregarding trade agreements. “As recent developments have demonstrated, it is unclear that the US can be relied on to honour agreements that it enters into going forward,” says Stephen Sidkin, partner and head of ESG at Fox Williams law firm.

The ripple effects of tariffs extend far beyond the balance sheets of brands and retailers — they strain international relationships, disrupt contractual obligations and push businesses into murky legal territory. Apparel companies could find themselves facing unintended breaches of contract, exposing them to costly and complex disputes.

Tariffs are already complicating nearshoring efforts. While many US fashion companies are eager to expand sourcing within the Western Hemisphere, new tariffs on textile and apparel imports from Mexico and Canada — both USMCA members — are sending mixed signals. Rather than incentivising close-to-market production, the policy is dampening enthusiasm for reshoring, says Dr Sheng Lu, director of the department of fashion and apparel studies at the University of Delaware.

McGrath sees a potential silver lining. The presence of tariffs could make vertical integration a more attractive strategy, giving brands greater control over production and mitigating the risks associated with sudden trade policy shifts. But transitioning to vertically integrated operations is costly and prohibitive for most companies.

A looming recession

Even as the fashion industry continues to repair supply chains fractured by the pandemic, it now faces fresh instability. The traditional pillars of sourcing — low-cost production, Tier 1 supplier prioritisation, regional concentration, historical demand modelling and bulk distribution — are all under scrutiny, McGrath continues.

A growing concern is that Trump’s tariff war could push the US economy into recession, says Gary Hufbauer, senior fellow at the Peterson Institute for International Economics. Slumping consumer confidence and cautious spending suggest brands may soon need to brace for a downturn. “With all the uncertainty, firms will put expansion plans on the shelf,” he warns. “All signs point to a US recession, and a slower global economy.”

For now, the industry remains in flux, forced to play a waiting game. “The fluid nature of the new normal in trade relations has yet to play out fully,” says FIT professor Quan. “It will be an ongoing game of wait and see, then adjust and reset as stakeholders reassess their position and take actions or counteractions to offset.”

Comments, questions or feedback? Email us at [email protected].