The transportation industry’s sustainability is in a period of its ‘peak complexity’ due to many overlapping regulations for clean vehicles and fleets and numerous new technologies introduced, particularly related to charging infrastructure.

This is according to a fifth annual State of Sustainable Fleets market report, presented at the Advanced Clean Transportation (ACT) Expo in Las Vegas, Nev., on May 20th.

This comprehensive industry report examines the current state of adoption of natural gas, propane, battery electric, and hydrogen fuel-cell electric vehicles, against a baseline of diesel and gasoline vehicles. The analysis is based on publicly available data and information collected from surveys of around 200 early fleet adopters across the U.S.

Investment and innovation balance

“Today, the problem is information overload. How does a fleet manager keep track of all of these developments, innovations, new regulations and funding opportunities?” said Nate Springer, vice-president of market development at TRC companies. He added the industry is meeting the complexity with ‘unprecedented investment and innovation.’

Amid 11 states adopting ACT and advanced clean fuel (ACF) rules, significant investments – $32 billion (all figures US) of public funds per year – are made in the U.S., aimed to make renewable diesel and renewable natural gas more accessible (substitutes for diesel and CNG engines, respectively), and develop new charging business models.

The U.S. will also see the opening of multiple new charging depots, along with various leasing and service-based offerings available in the market now. A more powerful natural gas engine is expected to be released later this year, too. There are also investments made to develop the national hydrogen fueling infrastructure through the Department of Energy’s hydrogen hubs program, as well as plans to introduce hydrogen combustion engines to the market in the next few years.

“This year, we see the perfect combination of investments in innovation to make fleets more sustainable today with available often drop-in solutions while laying the groundwork for even greater sustainable transformation of the fleet industry tomorrow,” Springer said.

However, the rapid rollout of varying – and sometimes conflicting – regulations led manufacturers to adopt different strategies, causing further confusion among fleet owners, and complicating their efforts to comply. Of the fleets surveyed, 63% of fleets that already apply efficiency technologies expect diminishing returns from efficiency gains in the future. “They realize that they will need new strategies to meet their own sustainability and operational goals,” said Springer.

BEVs adoption

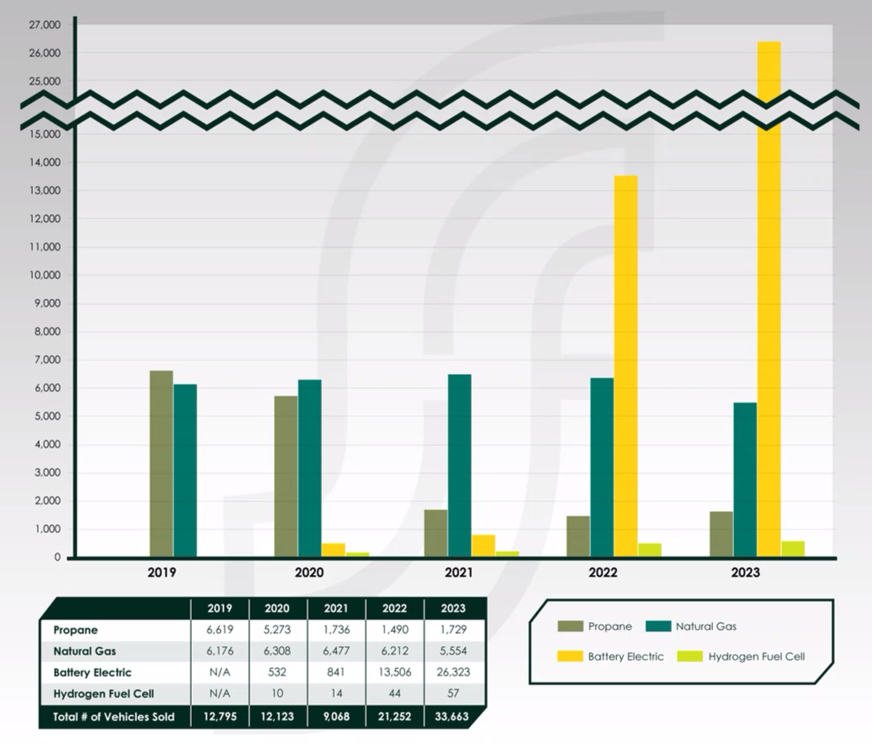

In 2023, the number of battery-electric vehicles (BEVs) has nearly doubled the 2022 volume, reaching more than 26,000 units. Of those, 90% were medium-duty cargo vans and trucks from Ford and Rivian, according to the report.

However, the transition to BEVs is complicated with certain challenges, like gaps in charging infrastructure, and supply chain delays. To address these issues, there has been a significant increase in funding and invention, with many new depot charging solutions and leasing or service-based charging options becoming available this year.

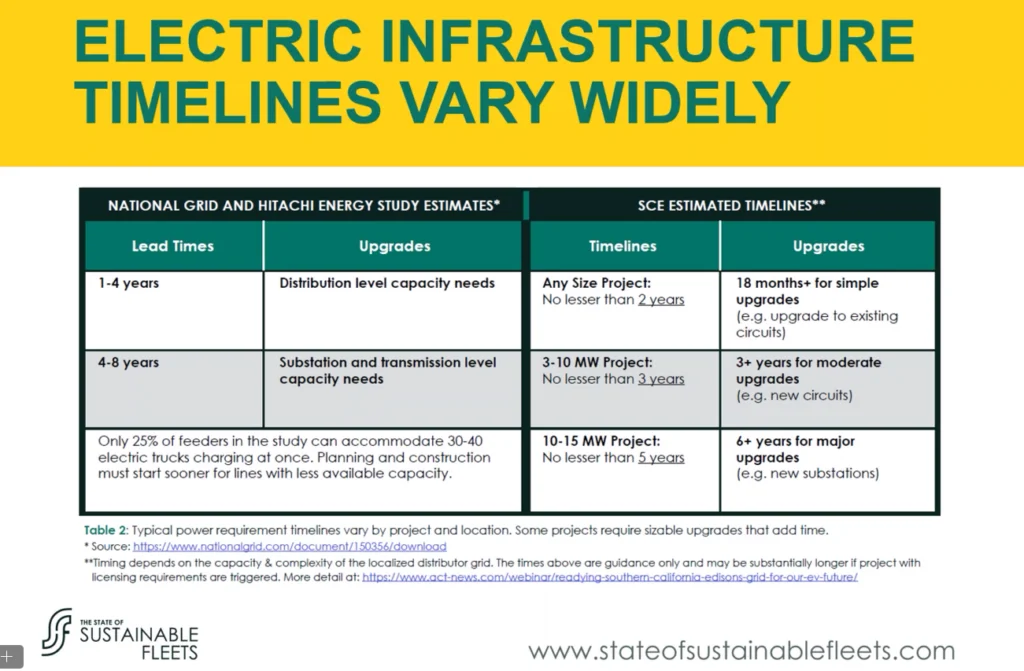

The fleets surveyed say they feel the scale of upgrades required for electrification, even for some small and medium-sized projects, leads to substantial financial investments. These projects often face lengthy lead times due to the complexities of siting, permitting, and interconnection. Only 25% of locations in the study could support the simultaneous charging of 30 to 40 heavy-duty trucks, requiring grid upgrades that could take four to eight years.

Near zero might be the answer for now

The use of renewable diesel as a direct substitute for traditional diesel is on the rise, too, with a 68% year-over-year increase in national use in 2023, amid credit volumes in California increasing 17% compared to two years ago.

The renewable diesel’s growth in both capacity and demand is driven by lower carbon fuel standards, which have significantly incentivized its market, particularly in the Western States, said Nuray Elci, Chevron’s vice-president of innovation and technology venture. Both biodiesel and renewable diesel are produced from the same feedstocks but processed differently — one with alcohol and the other with hydrogen — resulting in lower emissions and a substantial impact on reducing fleet carbon intensity.

“A lot of the refiners have either changed their hydrotreating units to enable the production of renewable diesel or they have built some new units to increase the capacity. So, you’re really seeing a continued desire to build some more,” she said.

Meanwhile, compressed natural gas (CNG) has proven to be a solid fit for many heavy-duty fleets with refuse, transit, dedicated operations, and more. Its average retail price was 50% less expensive than diesel last year.

According to the survey responses, fleets using CNG meet 70% of their fueling needs with renewable natural gas (RNG). In 2023, there were 150 new RNG facilities opened in the U.S., and Cummins X15N, a lighter and stronger 500-horsepower engine that runs entirely on natural gas, will be available this year, leading to further growth in natural gas vehicle sales. To fill the charging gap, some fleet owners used linear generators and temporary charring solutions fueled by propane and natural gas.

Infrastructure gaps

To address the infrastructure gap on a bigger scale, fleets and utility providers have to change their way of thinking, said Drew Cullen, senior vice-president of fuels and facilities services with Penske. Fleets are used to conventional fueling methods, which are predictable and reliable. However, transitioning to zero-emission technologies requires a different approach to where and how fuel.

“From a utility perspective, they also need to think much differently about this, right? They’re so used to providing energy to a stationary source,” he said. “There’s going to be more and more vehicles, right to provide that energy to whether it’s, you know, be a battery electric or providing energy for conversion of hydrogen or providing natural gas for hydrogen as well.”

But infrastructure needs vary for each solution, adds Elci. She says adapting to drop-in solutions such as renewable diesel or biodiesel is much simpler in comparison to the other solutions, as it allows for an easy transition, leveraging the current diesel distribution systems and vehicles.

“As you continue to go to RNG, you have existing infrastructure, but you need some new vehicles, and you do have to develop some infrastructure for the fueling — which is something we’re rigorously investing in and continuing to develop,” Elci said.

“I think there is a continued valuation of what that can bring, as it is significantly lower carbon intensity. And then as you continue to go in that spectrum with hydrogen, that’s certainly more significant infrastructure all the way – from supply to transportation, and in the trailers, and actually building the stations. There is a complete change there, which makes that a longer-term transition with some shorter-term wins.”

Hydrogen

Meanwhile, hydrogen technology is gradually becoming a viable option, too. However, according to the study, the prices will have to drop to $8-10 per kg to be competitive with diesel. In 2023, the price doubled compared to 2022 – some light-duty stations in California charge from $20 to $36 per kg.

The U.S. Department of Energy released $7 billion in funding to build seven hydrogen hubs across the 16 states. At the same time, the transportation industry is investing in bringing H2 combustion technology to the market in the next few years, said TRC’s Springer.

The word on the street is that for long-haul trucking operations, hydrogen route is the way to go, while BEVs are better suited for shorter distances.

Keith Brandis, Volvo’s vice-president of partnerships and strategic solutions, says the role of hydrogen hubs in achieving the necessary scale to reduce costs, which is critical for widespread adoption. But he also highlights concerns about hydrogen distribution due to its unique properties.

“Hydrogen being the smallest element, you have to have very specific seals and pipe pumps and pipes and everything else, which we plan to have on our vehicle at very high pressure. Some are talking about liquid approaches, but it will also require adaptations to the vehicles for hydrogen storage, but it will allow longer distances and shorter fueling times.”

Brandis adds that Volvo is exploring both compressed and liquid hydrogen storage solutions, which must be adapted for vehicle integration. These technologies promise longer driving ranges and shorter fueling times compared to traditional fuels. The company is currently testing hydrogen fuel cell vehicles in various climates, from extremely cold to very hot, to ensure reliability and effectiveness across different environmental conditions.

“We’re continuing that development in order to be ready in the latter half of the decade,” Brandis said.