Renishaw, headquartered in Wotton-Under-Edge, Gloucestershire, has launched its Tempus™ technology, a new process reported to enable users of its metal Additive Manufacturing machines achieve significantly higher productivity, with no reported reduction in part quality.

WE ARE AT FORMNEXT. COME MEET US ON BOOTH 11.0 C78.

Get all the latest news and updates from the show as they happen.

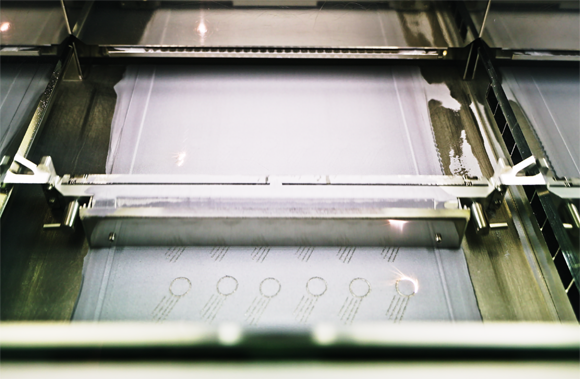

Unveiled at Formnext 2023, Tempus incorporates a new scanning algorithm for Renishaw’s RenAM 500 series of metal AM machines, which allows the laser to fire while the recoater is moving, saving up to nine seconds per build layer. Over the cycle time of the build, the time saving can cut the build time by up to 50%.

In Tempus technology, the recoater spreads a layer of powder, the lasers then follow the recoater, melting the powder being spread before the recoater completes its stroke. When the recoater goes back to the doser to collect more powder, the lasers pass over the recoater and continue melting the current layer, mitigating wiper time. As the recoater begins spreading the next layer of powder, the lasers finish the previous layer, and simultaneously starts processing the new layer. Tempus technology reduces the dwell time per layer, shortening cycle times.

The process works using advanced scanning algorithms that sequence the layer data in a way that maximises productivity, while maintaining part quality. The optimisation suits some part geometries more than others, adds Renishaw, but all geometries can see some productivity benefits. Those parts with thin, vertical features, for example, are likely to experience higher productivity savings.

“Reducing cost per part is critical to the wider adoption AM technology,” explained Louise Callanan, Director of Additive Manufacturing at Renishaw. “The dominant contributing factor to part cost for most components today is the time spent building the part on the machine itself. Reducing the amount of machine time per part therefore results in more cost-effective production.

“That’s why Tempus technology is such a big leap forward,” added Callanan. “Usually, the laser would turn off while the recoater is moving. Firing the laser while the recoater is moving minimises the laser off-time per build. The time and cost saving TEMPUS brings will open AM up to mass production applications where the technology would previously have been unviable.”

Tempus technology is standard fitment with new RenAM 500 Ultra metal AM machines, which are available with quad or single laser configuration. Existing RenAM 500 series customers can access Tempus as a paid upgrade. Renishaw data shows that retrofitting Tempus technology to an existing system is the equivalent of adding an extra laser, and allows existing customers to make the most of their machine investment.

For further information visit Renishaw at Formnext, Hall 11.0, C11.

www.renishaw.com/am