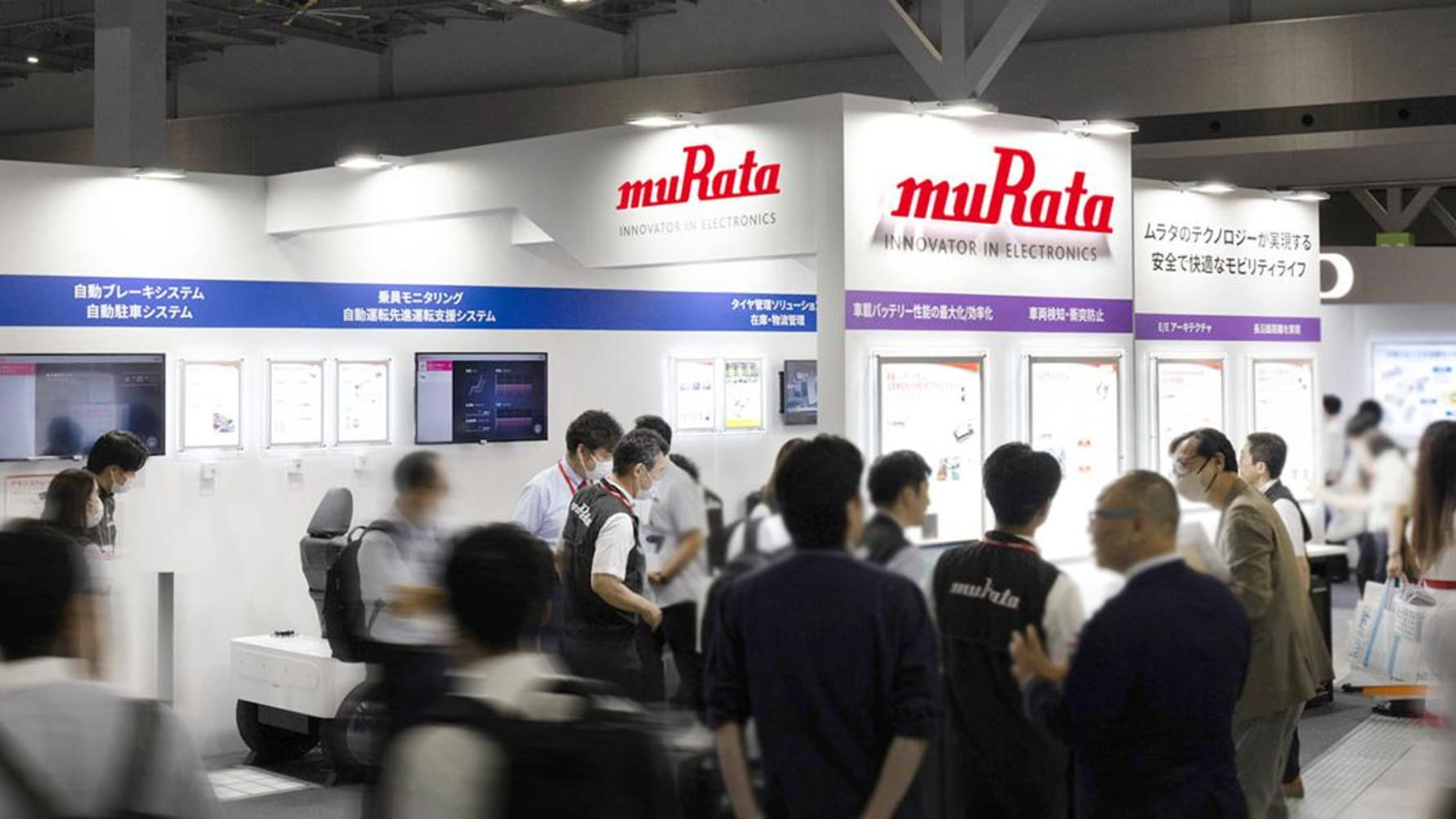

Murata Manufacturing participated in the Automotive Engineering Exposition (Society of Automotive Engineers of Japan, Inc.), one of the largest automobile technology exhibitions in the automobile industry in Japan. The exhibition was held in PACIFICO Yokohama in Yokohama from May 24 to 26, 2023, and in Aichi Sky Expo (Aichi International Exhibition Center) in Nagoya from July 5 to 7, 2023. We showcased Murata’s latest technologies and products, which are boosting initiatives in the electrification, automation, connectivity, and electronification of function control being promoted by the automobile industry.

It has been difficult for those involved in the automobile industry to visit in-person events held over the past few years during the COVID-19 pandemic. Many visitors actually came to this event to see, touch, and get a feel for the cutting-edge trends of the latest technologies. There was a lively exchange of questions and discussions about the exhibition with the explanation staff in the Murata booth. We received a great deal of praise and many suggestions. We now introduce here the technologies, products, and demos we showcased in our booth with a focus on the exhibition at the Nagoya venue.

Boosting the Evolution of Cars in Line with Connected, Autonomous, Shared, and Electric (CASE) with the Power of Electronic Components

The pace of efforts to achieve decarbonization and sustainability is increasing worldwide. The full-fledged growth period for electric vehicles (EVs) is finally arriving in the automobile industry. Meanwhile the functions of advanced driver assistance systems (ADAS), which are being equipped to more and more vehicles year by year, are also becoming more sophisticated. The development of technologies to further improve safety is underway. In addition, communication functions are now being equipped as standard to the majority of vehicles being launched on the market. Various services are now being provided by connecting with the cloud, surrounding cars, transportation infrastructure, and other technologies.

We proposed numerous solutions in the Murata booth to meet the demands of society and the automobile industry into which we have been unstintingly focusing our efforts on the best of the technologies we have continued to refine up to now. Visitors to our booth felt the effectiveness and value of those technologies through actual articles, panel exhibitions, demos, and other methods. We received a lot of feedback from those who are planning and developing technologies and products involved in the mobility industry such as the following:

“I would like to know the detailed information to be able to consider the advisability of adopting your technologies such as their functions, performance, price, and market launch timing.”

“I was astonished that it is possible to collect a surprisingly large amount of valuable information from inside and outside cars using sensors.”

“I visited the booth to see the actual articles and demos of your latest technologies, which I had learned about with information in advance. They met my expectations.”

“I want to take back information with me to consider whether we can utilize the solutions you have proposed as a means of solving our company’s challenges.”

Murata wants to sincerely listen to such opinions of those in the automobile industry and work closely together with them to jointly develop and provide solutions of electronic components with value that will boost the further evolution of automobiles. We will contribute to the realization of a smart and comfortable mobility society by developing and providing solutions as an innovator in the electronics industry. Those solutions include passive components such as capacitors with outstanding reliability, sensors for advanced safety systems, and communication modules. Murata Manufacturing is constantly working hand-in-hand with the automobile industry toward the future.

Proposal 1: Toward the Realization of More Attractive EVs with Greater Convenience

Resin Molding SMD Type MLCCs for Noise Suppression, Supporting High-Value-Added EVs: EVA Series [New Product]

A movement is underway to increase the battery voltage from the approximately 400 V it has been conventionally to 800 V or more in the development of the latest EVs. The aim is to lengthen the traveling range and to shorten the charging time. The EVA series is resin-mold SMD-type multilayer ceramic capacitors for noise suppression in EVs. The series makes it possible to secure the creepage distance required under a high-voltage load that conforms to safety standards while being small and low profile (12.7 × 6.0 × 3.7 mm). These products can be utilized as noise suppression components that ensure high safety by applying them to EV on-board chargers (OBCs) equipped with high-voltage batteries in the 800 V class, motor drive inverters, and other products. Replacing the film capacitors and large single-layer capacitors used up to now has realized the downsizing of circuit substrates. This can contribute to expanding the vehicle interior space, improving the degree of freedom in the layout of electrical components and increasing the battery capacity. Moreover, mounting with reflow is also possible. Therefore, it also boosts a reduction in assembly costs.

Supporting the Higher Performance and Safety of Batteries for Electric Vehicles with High-precision Temperature Detection: SMD NTC Thermistors

It is essential to have fine thermal control based on high-precision temperature detection to reliably prevent thermal runaway when ensuring safety and improving the performance of electric vehicles equipped with large-capacity and high-output batteries. Murata provides AEC-Q200-compliant small and high-precision SMD NTC thermistors (temperature sensors) that can contribute to measures against thermal runaway in automotive battery cells. We also have a lineup of small products with a minimum size of 0.6 × 0.3 mm. The detection temperature precision is also high, with a minimum variance of 0.18°C at 25°C. There has been an increase in recent years in the number of battery modules for which the battery cells that were previously connected by cables have now been changed to a structure in which they are connected by flexible substrates. Surface mounting on flexible substrates becomes possible with SMD type NTC thermistors, which contributes to reducing the assembly cost for battery modules. In addition, mounting on flexible substrates means that the contact area between the sensor and the cell surface is widened, which realizes a high-speed response. As a result, it becomes possible to quickly detect the occurrence of anomalies and to take action against them before they become serious.

High Temperature Film Capacitors for Automotive for X in 1 Integrated Power Electronics

Functional integration is underway on the components of electric systems of inverters, motors, gears, on-board chargers (OBCs), DC-DC converters and other power electronics equipment as seen with E-Axle in anticipation of the spread of EVs. In the midst of this trend, high-capacity film capacitors used in circuits that handle high-voltage and high-current power are now required to be high-heat resistant and low-profile products that can handle the increase in power density. Murata has developed a high temperature film capacitor for automotive that meets these new demands by utilizing our knowledge of higher quality and downsizing that we have built up through the development of ceramic capacitors. Conventional film capacitors offered heat resistance of 85°C to 105°C. That was not sufficient for power electronics equipment with high power density. Murata has adopted film materials we have independently developed for the film capacitors we have developed. As a result, we have realized high heat resistance of 125°C to 135°C. This will contribute to the downsizing and lower weight of automotive power electronics equipment, which is becoming increasing integrated.

Proposal 2: Toward the Automation of Even Safer and More Comfortable Cars

Reform of Electrical/Electronic (E/E) Architecture and Electronic Component Groups That Meet the Demands of Autonomous Driving / ADAS

A movement is underway to reform electrical/electronic architecture (E/E architecture) to an even more efficient and effective configuration. The aim is to respond to the rapid progress in automation and electronic control in automobiles. Conventional distributed architecture is undergoing a transformation to a distributed domain type in which processing systems are distributed for each type of function in the latest vehicle models and to a centralized domain type in which functions are integrated in a central high-performance computer at the forefront of development. Against this backdrop, there is now a demand for electronic components that support the higher performance of SoCs equipped to electrical/electronic circuits, the decentralization of power supply architecture, and the increase in speed of automotive networks. Murata is optimizing the materials, construction methods, and structure of electronic components. That is allowing us to develop and provide electronic components that are small and with high reliability to comply with the demands of autonomous driving and advanced driver assistance systems (ADAS).

Realization of Even Safer Automatic Braking with Wide Range and High-precision Distance Detection: Ultrasonic Sensors [Under Development]

There is a need for ultrasonic sensors that can detect the distance between a vehicle and surrounding cars and objects over a wider range at high precision to realize safe automatic braking systems and automatic parking systems. Murata is currently developing ultrasonic sensors with further improved performance over both short and long distances. We have reduced the resonance frequency tolerance by 50% compared to what it was before, which has stabilized the distance detection performance in a range of up to a maximum of 550 cm. We have also reduced the capacitance tolerance by 50% compared to previously, which has shortened the minimum detection range that was 30 cm in conventional products to 15 cm or less to improve short-distance performance. Furthermore, we have realized compatibility with coding ICs through lowering the Q and standardizing the Q tolerance. We have also improved the temperature characteristics. Murata is also developing a millimeter wave radar solution in the 79 GHz band suitable for detecting the situation around vehicles such as to assist with parking.

Supporting Safe Driving by Constantly Watching over the Health Condition of Vehicle Occupants with Sensors: Vehicle Occupant Monitoring Sensors [Reference Exhibit]

Drivers need to be in good health at all times while driving to be able to drive safely. Murata is developing sensors that are used by being embedded into seats to be able to monitor the presence and condition of the occupants of a car by detecting biological signals such as breathing and heartbeats. High sensitivity, high resolution, and even wide-range measurement is possible. It is possible to separate while simultaneously measuring large load fluctuations due to the vehicle occupants sitting down on their seats and small load fluctuations from breathing and heart movements with one sensor. It will be possible to use these sensors in ensuring safety by watching over the health condition of the driver, high-performance seatbelt reminders that can distinguish between objects placed on a seat and vehicle occupants, vehicle occupant detection to safely activate airbags, and other applications. Murata is also developing a millimeter wave radar solution in the 60 GHz band suitable for detecting children who have been left behind in vehicles among other purposes.

Accurately Identifying Vehicle Location Even in Places Where GPS Radio Waves Do Not Reach: SCHA600 Inertial Force Sensor

It is essential to adopt sensing means that can identify vehicle location with high precision to realize safe autonomous driving systems and advanced driver assistance systems (ADAS). However, it is difficult to identify vehicle location in places where GPS radio waves do not reach such as in tunnels. The SCHA600 is a 6-axis one-package inertial force sensor that realizes high-precision motion detection and location detection. It supports data output with digital SPI communication. The detection range is ±125 dps or ±300 dps for gyro and ±6 g for acceleration. Moreover, it can be applied to system development requiring ASIL-D at the level of functional safety. It comes with outstanding vibration resistance characteristics. It can also be equipped with a constant self-diagnosis function to enable it to detect anomalies in a wide range in addition. It is compliant with AEC-Q100.

Proposal 3: Toward the Realization of Connected Cars That Can Be Reliably Connected in Various Settings

Communication Module for V2X Compliant with Two Major Standards: Type 1YL and Type 2AN

To realize autonomous driving, it is necessary to have a mechanism that collects information that cannot be detected with sensors equipped to a vehicle alone from surrounding cars and traffic infrastructure such as traffic lights. It is essential to equip vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communication functions to realize that. Type 1YL and Type 2AN are communication modules for V2X developed for the first time by Murata that are compatible with both the DSRC method (compliant with IEEE801.11) and the cellular V2X method (3GPP Release 14/15 and PCS compliant). We have equipped the modules with a chipset compliant with the AEC-Q100 made by Autotalks Ltd., which is a world leader in the V2X chipset market. We have produced modules with high quality, robustness, and performance level by utilizing Murata’s high-frequency RF design technologies and unique high-density mounting technologies. The standard method that must be supported differs by country and region with V2X. However, it is possible to easily support the requirements of the destination country with Type 1YL and Type 2AN.

Tires with Built-in RFID Boosting Digital Transformation (DX) in the Transportation Industry

Reducing the downtime of trucks when inspecting and repairing tires and similar challenges are urgent issues in the transportation industry, which is suffering from a shortage of workers. Murata has developed a type of RFID built into tires jointly with Michelin SCA. This is a technology that will boost the promotion of digital transformation (DX) in the transportation industry. Utilizing this type of RFID built into tires we have developed will make it possible to improve the efficiency of tire management work such as with inventory and logistics management, records of the remaining tread on an individual tire basis, and records of the retread (restoration) history. It is a small (1.8 mm in height and up to 40 mm in width) tag using UHF band RAIN RFID (865 to 920 MHz). It is also durable enough to withstand impacts during tire processing and traveling. In addition, it is possible to realize good communication characteristics even after being built into tires by applying Murata’s unique antenna design

Proposal 4: Murata’s Technologies and Products Supporting the Further Evolution of Cars

Realizing Safe Driving by Visualizing Driver Fatigue in the Freight and Transport Industries: MF100 Fatigue Stress Meter

Appropriate driver fatigue management is being sought for safe driving in the transportation and public transport industries. Manufacturing sites, including those in the automobile industry, are also facing the same issue to ensure safety and improve efficiency. The MF100 is a fatigue stress meter that easily visualizes fatigue at high precision by detecting fluctuations in the heartbeat. It quantifies the condition of the autonomic nerves based on heartbeat and pulse data detected non-invasively using Murata’s sensors. Information is extracted on the balance and deviation value of sympathetic and parasympathetic nerves by analyzing the big data accumulated by the technology with a medically backed algorithm. This visualizes the fatigue and stress level, which are difficult to objectively assess, to provide support including for employee health management and work environment improvement activities at manufacturing sites. Moreover, it is also possible to utilize this meter in applications such as the objective assessment of the effect of developed products in the development of comfortable equipment to be equipped to cars.

Embedding Sensors and Communication Functions into Streetlights to Watch over Residents and Society: Smart Pole Compatible Technology

It is expected that smart poles, which integrate diverse functions including 5G base stations and environmental sensing into streetlights, will be an important element to watch over people and to efficiently and effectively grasp social activities in smart cities. Murata will continue to contribute to the increase in sophistication of smart poles by developing and providing various sensors to detect traffic volume, the coming and going of people, the CO2 concentration in the atmosphere and other data, diverse communication modules, and other products. We entered into a comprehensive partnership with Nagaokakyo City in Kyoto Prefecture in May 2023. We will actually install smart poles there by the end of the year. We will then strive in the future to achieve carbon neutrality together with power storage and generation.

Simulation Software for Designers: Femtet

Femtet is user-friendly analysis simulation software that meets the diverse analysis needs of developers and designers by combining eight analysis functions in one package. Finite element analysis of electromagnetic waves, magnetic fields, electric fields, stress, heat conduction, fluid, piezoelectricity, and sound waves, as well as coupled analysis of those elements, can be easily performed, like using a calculator. A database management function for materials, boundary conditions, body attributes, and models is equipped as standard. The data created by each user can be shared and used by an entire development team. This is software produced in Japan that Murata has made unique improvements to over about 40 years.

In addition to technologies and knowledge accumulated within the automobile industry up to now, innovation based on new ideas cultivated in other industries is becoming necessary to accomplish the revolution being undertaken by the automobile industry. Murata has accumulated materials technologies, process technologies, product design technologies, production technologies, and software technologies, analysis and evaluation technologies which support them, and other such technologies by developing, producing, and selling ceramics-based electronic components. We will utilize these technology foundations to make creative products and solutions that will boost the evolution of automobiles. This will contribute to the further development of the automobile industry and the realization of a smart and comfortable mobility society.

The content of this article is based on information available at the time of our participation at the exhibition. Please understand that it may differ from the latest information.