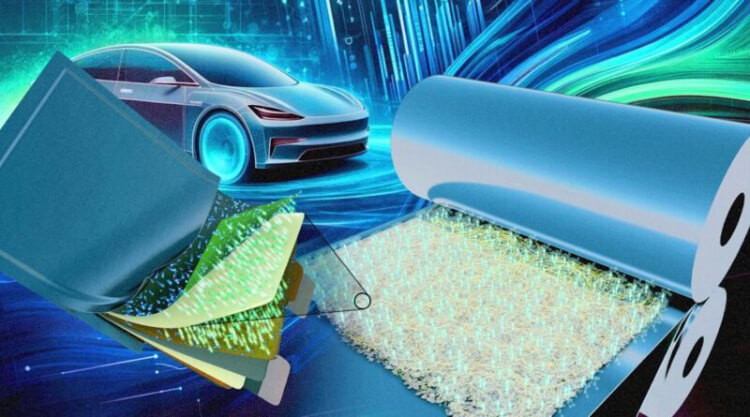

Researchers at Oak Ridge National Laboratory have developed a thin, flexible solid-state electrolyte that has the potential to double energy storage in next-generation vehicles, cell phones, laptops, and other devices. Credit: Adam Malin/ORNL, U.S. Dept. of Energy

Researchers at a prominent university have made a groundbreaking discovery in solid-state electrolytes that could significantly transform energy storage for next-generation vehicles. By doubling the energy density compared to conventional lithium-ion batteries, this advancement promises longer driving ranges and faster charging times for electric vehicles. The new solid-state electrolyte also addresses safety concerns associated with current battery technologies, offering a more stable and reliable option for automotive applications. As automakers and consumers eagerly anticipate the commercialisation of this technology, the implications for the electric vehicle industry are profound.

Key Things to Know:

- Solid-state electrolytes offer double the energy density of conventional lithium-ion batteries, enhancing driving ranges and reducing charging times for electric vehicles.

- These electrolytes provide improved safety over liquid electrolytes by reducing risks of leakage, flammability, and thermal instability.

- The development of flexible, sulfide-based solid-state electrolytes allows for compact, high-performance batteries suitable for extreme environments like space.

- Although solid-state technology holds great promise, challenges remain in scaling production and reducing costs for widespread adoption.

How does the increased energy density of solid-state electrolytes impact the design and performance of electric vehicles, what challenges remain in scaling up production of solid-state batteries for mass adoption in the automotive sector, and how might this innovation influence the overall sustainability of electric transportation on a global scale?

What challenges do solid-state batteries face?

Battery technology has indeed experienced significant advancements over the years, evolving from simple electrochemical cells to complex systems capable of storing substantial amounts of energy. The quest for higher energy density, coupled with demands for smaller and lighter batteries, has driven the development of new electrolytes and advanced materials. These innovations have not only improved the performance of batteries but have also expanded their applications across various sectors, including mobile devices, electric vehicles, and large-scale energy storage systems.

One of the most promising developments in this field is the emergence of solid-state batteries. This technology differs fundamentally from traditional liquid-based batteries. Conventional batteries typically use a liquid electrolyte solution to facilitate ion transport between the anode and cathode, which are the negative and positive terminals, respectively. In contrast, solid-state batteries employ a solid electrolyte, which can be made from ceramics or solid polymers. The use of a solid medium offers several potential advantages over liquid electrolytes, including enhanced safety, as they are less prone to leaking and can be more resistant to fire and other hazardous conditions. Moreover, solid-state batteries could potentially be made stronger and lighter, attributes that are highly desirable in many applications.

Advantages and Challenges of Solid-State Battery Technology

Despite these advantages, the transition to solid-state technology is fraught with challenges. Contrary to the assertions in the initial outline, solid-state batteries can actually offer higher energy densities than their liquid counterparts, which is one of their main selling points. However, they do face significant technological hurdles that have hindered their widespread adoption. One of the primary challenges is the current cost of production. The materials and manufacturing processes required for solid-state batteries are still in the developmental stage, leading to higher costs compared to conventional batteries. This economic factor makes it difficult to integrate solid-state batteries into existing product designs, particularly in cost-sensitive markets.

Furthermore, while solid-state batteries are indeed lighter when considering energy density, their overall weight and volume can still be optimised. The interfaces between the solid electrolyte and the electrodes pose significant challenges; poor interface contact can lead to increased resistance and decreased performance. Addressing these interface issues is critical for improving the efficiency and longevity of solid-state batteries.

Another significant hurdle is the scalability of the technology. While laboratory prototypes and small-scale production have demonstrated the potential of solid-state batteries, scaling up to mass production remains a formidable challenge. The intricate processes and precise conditions required to manufacture these batteries must be replicated on a larger scale, which is a complex and costly endeavour.

Lastly, the cutting-edge nature of solid-state battery technology means that it is not yet widely available on the commercial market. Researchers and developers are still exploring ways to enhance the performance and reliability of these batteries, and it may take several more years before they become a viable option for widespread use.

Researchers develop new electrolyte that could help solid-state batteries

In a significant breakthrough that promises to reshape the battery industry, researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL) have developed a new, thin, flexible solid-state electrolyte. This development could potentially double the energy storage capacity of batteries, impacting everything from electric vehicles to mobile devices such as laptops and smartphones.

The new solid-state electrolyte, crafted from a specially optimised polymer binder combined with sulfide solid-state electrolytes, offers a safer and more efficient alternative to the liquid electrolytes currently prevalent in battery technology. Liquid electrolytes, while effective, pose risks due to their flammability and chemical reactivity. They are also prone to leakage and thermal instability.

Advantages of Sulfide-Based Solid-State Electrolytes

The integration of sulfide-based solid-state electrolytes presents a notable improvement in terms of both thermal stability and ionic conductivity. By leveraging sulfides, this approach addresses a major limitation in traditional polymer electrolytes, which tend to underperform in environments where higher conductivity is essential. This advancement not only ensures better performance but also enhances the overall longevity of battery systems in demanding applications such as electric vehicles and portable electronics.

Guang Yang, a leading researcher at ORNL, highlighted the potential of this innovation, stating, “Our achievement could at least double energy storage to 500 watt-hours per kilogram.” He explained that the primary goal was to create ultra-thin membranes, no thicker than 30 micrometres, to enhance the packing density of energy in lithium-ion batteries. This could significantly extend the operational life of batteries before needing a recharge, a boon for both consumer electronics and electric vehicles.

This increase in energy density is pivotal for industries like electric vehicles, where the demand for more compact and powerful energy sources continues to grow. By achieving higher energy storage with thinner membranes, these solid-state electrolytes also improve safety by reducing the risks associated with overheating and electrical shorts, common issues in conventional liquid electrolyte systems.

Energy Density and Safety Enhancements in Solid-State Electrolytes

The research team’s efforts have also focused on the scalability of these solid-state electrolyte sheets. They are designed to prevent electrical shorts by effectively separating the negative and positive electrodes, thus providing a high-conduction path for ion movement. This structural innovation not only enhances battery safety but also improves overall performance and energy density.

Ensuring scalability in solid-state battery production is essential for widespread commercial adoption. Recent advancements suggest that optimising the polymer binder for mass production could simplify the manufacturing process, making it economically viable for large-scale deployment in consumer electronics and automotive industries. This breakthrough helps overcome one of the most significant hurdles in solid-state battery technology: cost-effective mass production while maintaining performance integrity.

The study, detailed in the journal ACS Energy Letters, also delves into the critical role of the polymer binder’s molecular weight in creating durable electrolyte films. Films utilising heavier binders with longer polymer chains exhibited greater structural integrity and ion conductivity, an essential factor for the stability and efficiency of the battery.

Beyond just molecular weight, the precise control of the polymer’s structural properties has proven critical in achieving a balance between mechanical strength and ionic conductivity. The ability to maintain structural stability while promoting efficient ion transport positions this material as a key enabler in the future of high-energy-density batteries, particularly in applications where reliability and longevity are crucial.

Optimising Polymer Structure for High-Performance Batteries

Collaboration has been key to this project’s success. Yang worked alongside Jagjit Nanda, the executive director of the SLAC Stanford Battery Center, and a team of experts from various institutions, including Florida A&M University-Florida State University College of Engineering and Freed-Hardeman University. Advanced characterisation techniques like scanning electron microscopy and electrochemical impedance spectroscopy played pivotal roles in analysing and refining the electrolyte’s properties.

Looking ahead, the ORNL team is preparing to integrate this innovative thin film into next-generation battery electrodes to conduct practical tests under real-world conditions. They plan to collaborate with industry, academia, and government partners to further develop and test the technology in various applications.

How could solid-state batteries change the future?

The advent of solid-state batteries represents a significant leap forward in the field of energy storage technology. Unlike their liquid electrolyte-based counterparts, solid-state batteries utilise a solid electrolyte, which can be a game-changer in various applications, particularly in electronics.

The Safety Benefits of Solid-State Batteries

One of the most compelling advantages of solid-state batteries is their inherent safety features. Traditional batteries, such as lithium-ion batteries, employ a liquid electrolytic solution that can pose risks of leakage, swelling, and even explosion under certain conditions. In contrast, solid-state batteries eliminate the use of a liquid electrolyte, thereby reducing the risk of such hazardous events. This characteristic alone makes solid-state batteries an ideal candidate for use in electric vehicles (EVs) and mobile devices.

In electric vehicles, battery safety is paramount, given the large size and energy requirements of the batteries used. Similarly, in mobile devices, user safety cannot be compromised, making solid-state batteries a highly attractive option.

Moreover, the absence of a liquid component in solid-state batteries allows for more compact and versatile designs. Traditional batteries are often limited by the need to accommodate liquid electrolyte expansion, which can lead to swelling. This swelling not only affects the battery’s longevity and performance but can also impose design limitations on the device. Solid-state batteries, free from the risk of swelling, offer greater flexibility in design. This can lead to the development of thinner, lighter, and more efficient devices, as manufacturers are no longer constrained by the physical expansion of the battery’s components.

Design Flexibility and Extreme Environment Suitability of Solid-State Batteries

In addition to safety and design advantages, solid-state batteries also hold great promise for use in extreme environments, such as space travel. The vacuum of space presents unique challenges for traditional liquid-based batteries. In such an environment, the liquid electrolyte can boil off or freeze, depending on the external temperatures and pressure conditions, which can severely impair the battery’s performance and longevity. Solid-state batteries, with their solid electrolytes, are not affected by the vacuum of space, making them more stable and reliable under such extreme conditions. This reliability is crucial for space missions, where every component’s performance can impact the success of the mission.

In conclusion

The development of solid-state batteries could indeed reshape the field of electronics by providing safer, more compact, and reliable energy storage solutions. Their potential to enhance the safety of electric vehicles, enable more innovative designs in mobile devices, and operate reliably in extreme conditions like space underscores the transformative impact solid-state technology may have on our future technological landscape. As research and development in this area continue, we may soon see these theoretical benefits become a practical reality, changing the way we use and interact with electronic devices in significant ways.