To Joseph Salama it is clear that the UK’s independent garages will have problems serving customers with electric cars: “You can see it’s going to happen, actually it’s already here.”

The owner of specialist Volkswagen workshop Jack’s Garage in London’s North Kensington explained: “It’s very challenging for the independent workshop to be able to afford not just the costs . . . but the revenue lost to train people up [as electric vehicle mechanics] . . . and then they’ve got to practise.”

Despite having far fewer moving parts than traditional cars, EVs can be a repair challenge for smaller garages because of their heavier reliance on software and their high-voltage batteries that require specialist training to handle.

Although Jack’s, which is full to overflowing with cars and vans, does offer to convert cars to run on electric power, it does not work on new EVs and at the moment has no plans to start. According to Salama his garage, like many others, has been priced out of the market by a combination of the high software costs and other barriers to training staff that include record vacancy rates across the industry.

As the UK dithers about a date for banning the sale of new internal combustion engines, pushing it recently from 2030 to 2035, nationwide data, plus the experience of individual garages, point to a looming skills shortage that could leave electric car drivers queueing for a mechanic if they have a breakdown.

“We were making good progress but this definitely won’t help, this indecision,” said Steve Nash, chief executive of the Institute of the Motor Industry, a lobby group.

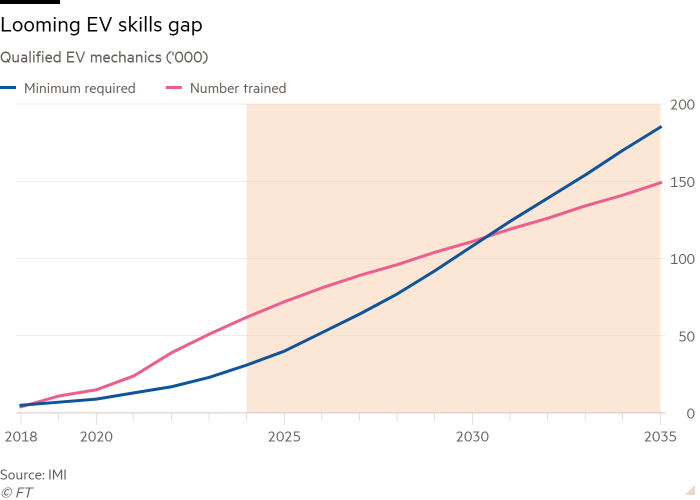

The scale of the challenge was shown last week when the IMI published forecasts predicting a skills gap of 8,000 EV technicians by 2030, rising to 24,000 by 2032, as garages — faced with record vacancy rates, policy uncertainty and rising costs from inflation — push training down their list of priorities.

These pressures have meant that the IMI’s skill gap predictions, which had been improving in recent years, are moving in the other direction as training rates have begun to fall.

“It’s perhaps not surprising, given the enormous amount of uncertainty in the early part of this year about the ICE ban, that individuals working in the sector and their employers have taken their foot off the pedal on EV training,” said Emma Carrigy, research manager at the IMI. “It also appears that training budgets may be among the first to be cut in the face of challenging economic conditions.”

The IMI’s updated skills predictions show that 2,900 people qualified as EV mechanics in the second quarter of 2023, a 36 per cent drop on the same period last year. For the first half of this year, the number was down 26 per cent.

In total, 20 per cent of UK motor mechanics, or 45,300 people, are now also officially qualified to work on EVs. But training has been concentrated in the dealerships that sell most new cars and in roadside assistance services. It has been slower to take off in the independent garages that generally mend and service vehicles after the three-year agreements that tie them to their original dealerships end.

A shortage of mechanics across the industry plus economic headwinds from inflation have meant that garages are less willing and able to give up working hours and revenue while staff go to training courses, even with demand for EV mechanics rising.

“We’ve got record vacancies [across the industry], something like 24,000,” said Nash, “so it’s difficult for [independent garages] to commit to training at the moment anyway.”

Andy Turbefield, head of quality at Halfords Autocentres’ car servicing business, told the Financial Times that the vacancy rate in the UK had been fuelled by decades of low investment in apprenticeships and training. Brexit had exacerbated the problem, he added, contributing to a “skills crisis” in the UK that was “absolutely” a factor in the shortage of EV mechanics.

Salama at Jack’s Garage told the FT that from an independent garage’s point of view, those factors made training much less straightforward: “If you’re short staffed, forget it . . . Just keep your head above water.”

“I can only afford one [mechanic in training],” he said, adding that “we’re always looking [to hire] . . . for years now”.

Some in the industry say that the government should help create the educational infrastructure to support the transition to electric vehicles, which will be an important part of meeting the UK’s net zero goals.

Nash at the IMI said it had previously asked for help with training costs. “It wasn’t vast amounts . . . we were talking about around £15mn, to put behind a training fund that the independent [garages] sector can access.”

If the barriers to training persist and the IMI’s skills shortage projections are correct, it will be customers that suffer, he added. “You don’t have the same level of price competition. It’s not a healthy situation to have from a market competition point of view.”

Turbefield suggested the government could make it easier for the industry to access money that it collects from big employers to fund apprenticeships. “The biggest help and support the government could do is release apprenticeship levy funding,” he said, adding that the UK should “change the standards for apprentices to include electric vehicle qualifications, because currently they don’t”.

Peter Melville, technical director of the Hybrid and Electric Vehicle Repair Alliance — a support organisation for garages — said: “I think it’s something that could be put in place further down the ladder at school. So that we have the right people.”

Of the UK’s more than 42,000 independent garages, 300 are Hevra members, servicing and working on EVs. Melville said that number would need to increase rapidly in the near future to match demand.

“In 2025 we would need to add another 300, and it’s taken us six years to get the first 300,” he said. “We’re looking to cross the 10,000-garage point in 2032.”